128 Tiny PLL

128 : Tiny PLL

- Author: LegumeEmittingDiode

- Description: 4-channel fractional-N frequency synthesizer

- GitHub repository

- Open in 3D viewer

- Clock: 10000000 Hz

Table of contents

- PLL

- ADC

- Top level

- PLL

- ADC

- Pinout and CSR address map

- Allowable output frequencies Physical design

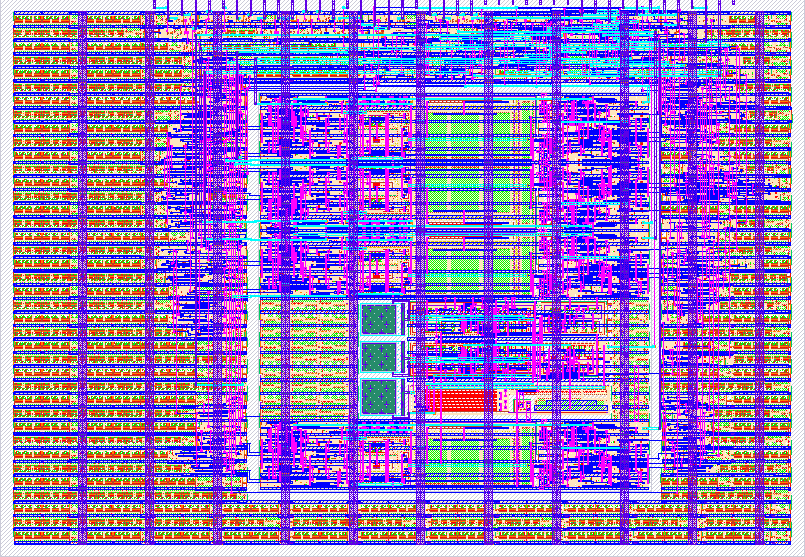

- Analog layout

- Digital synthesis

Circuit design

This project showcases tiny_pll, a completely self-contained fractional-N

frequency synthesizer using less than 6% of the area of a 1x1 TinyTapeout tile.

The design goals of this project were as follows:

- The design should be as simple as possible to reduce the chance of failure.

- The design should be as small as possible so it can be incorporated into future Tiny Tapeout designs with minimal area overhead.

There are 4 tiny_pll instances in this project. Each instance multiplies the

frequency of a reference clock by a rational number A/B, where A and B can be

between 1 and 15. Such a block has two main use cases:

- Generating several internal clocks from a single off-chip oscillator (e.g., for a large digital design with multiple clock domains)

- Generating one or more internal clocks at a higher frequency than what can be provided to the tile through the mux and GPIO pins

tiny_pll is designed for a 10 MHz reference input, which implies an output

frequency between 67 kHz and 150 MHz. The 4 output clocks are connected to the

GPIO pins uo[3:0]. In reality, the maximum output frequency is limited by 4

factors:

- The speed of the

sky130I/O cells, which itself is a factor of the off-chip load capacitance - The routing between the TT mux and the I/O cells

- The speed of the TT mux

- The routing between the project tile and the TT mux

A 1-bit delta-sigma ADC is included to allow measurement of the analog control

voltage on uo[4].

This design is inherently mixed-signal due to the analog nature of the PLL.

Consequently, the top-level layout is implemented as a custom analog/digital

section for the PLL and ADC, surrounded by RTL which implements the

control/status registers (CSRs) and various clock buffering and multiplexing

functions. Schematics were created using xschem and simulated with ngspice;

custom layout was done using klayout with the Efabless sky130 PDK; digital

synthesis and PnR was done using a custom OpenROAD flow; and magic and

netgen were used for LVS, DRC and parasitic extraction.

PLL

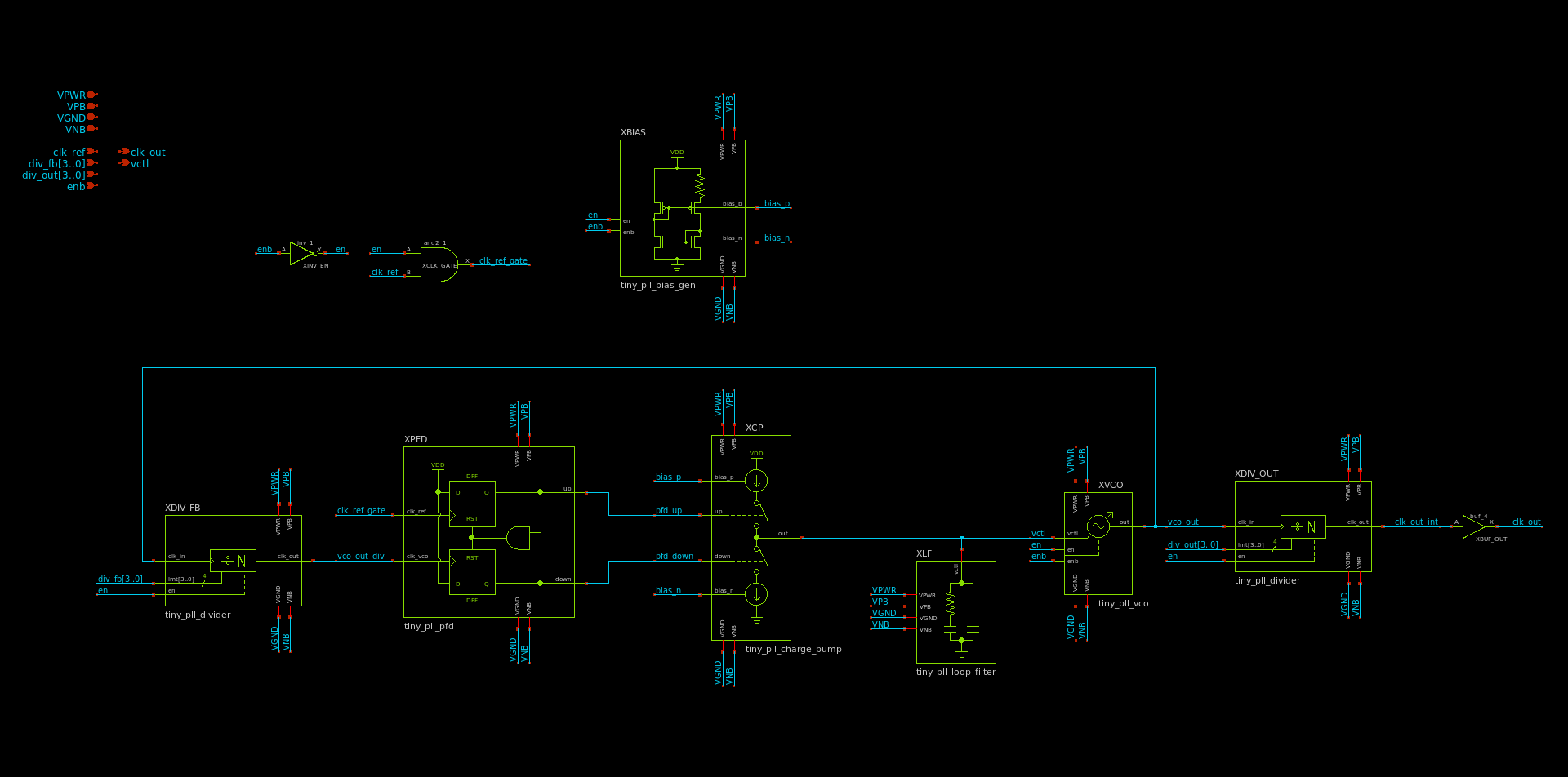

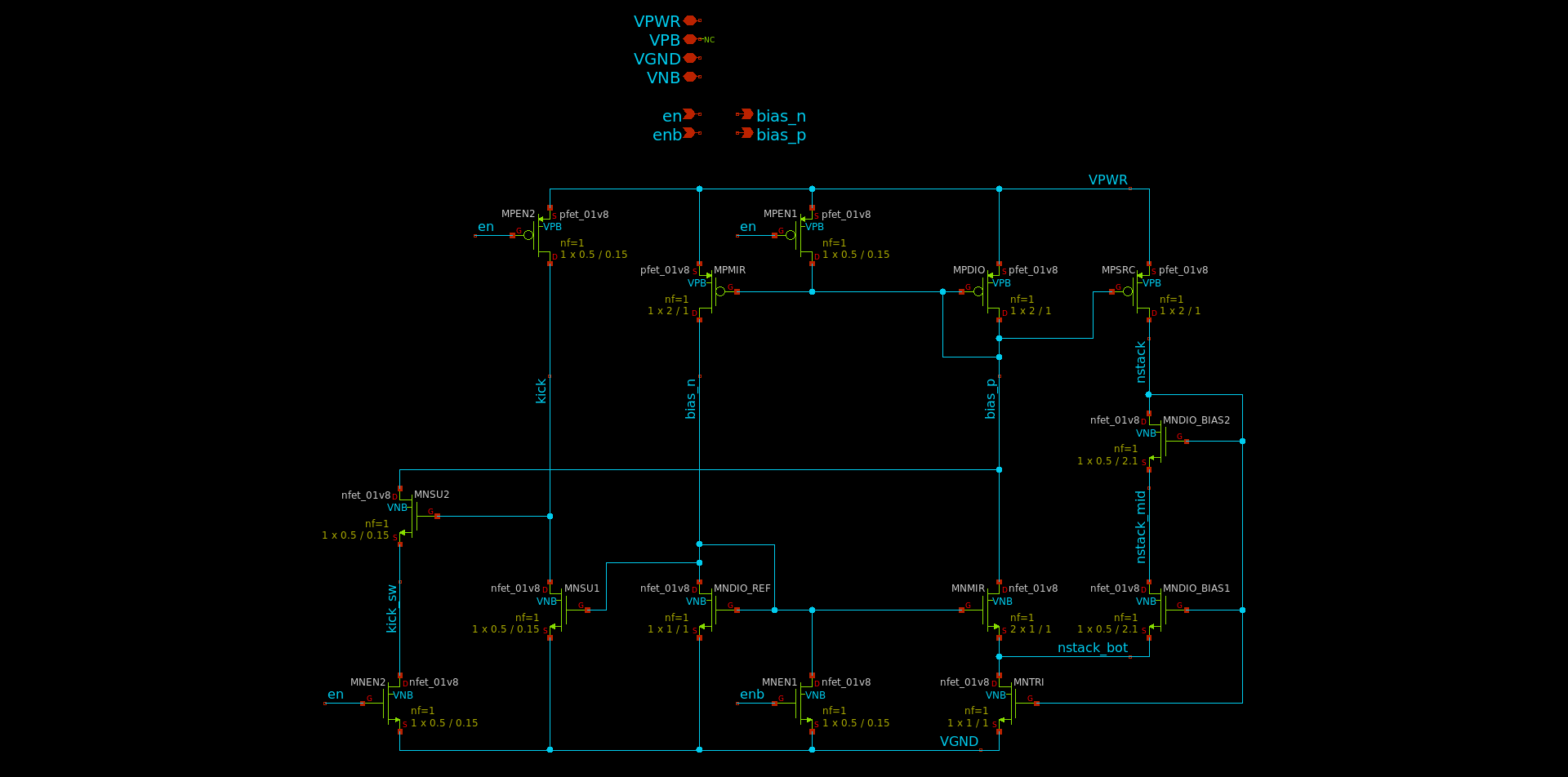

The top-level schematic of tiny_pll is shown below:

The PLL uses a standard fractional-N architecture, where an input and output

frequency divider are used to set the frequency multiplication with respect to

the reference clock input. The output frequency is A/B * f_ref, where A is

the division ratio of XDIV_FB, B is the division ratio of XDIV_OUT and

f_ref is the input clock frequency. Documentation for the PLL subcells is

included below.

Throughout the schematics, the pins VPB and VNB are included to connect the

bulk terminals of all PMOS and NMOS devices, respectively. This is done to

ensure the corresponding terminals of the standard cell instances at each level

of hierarchy are propagated to the top level and connected to VPWR and VGND.

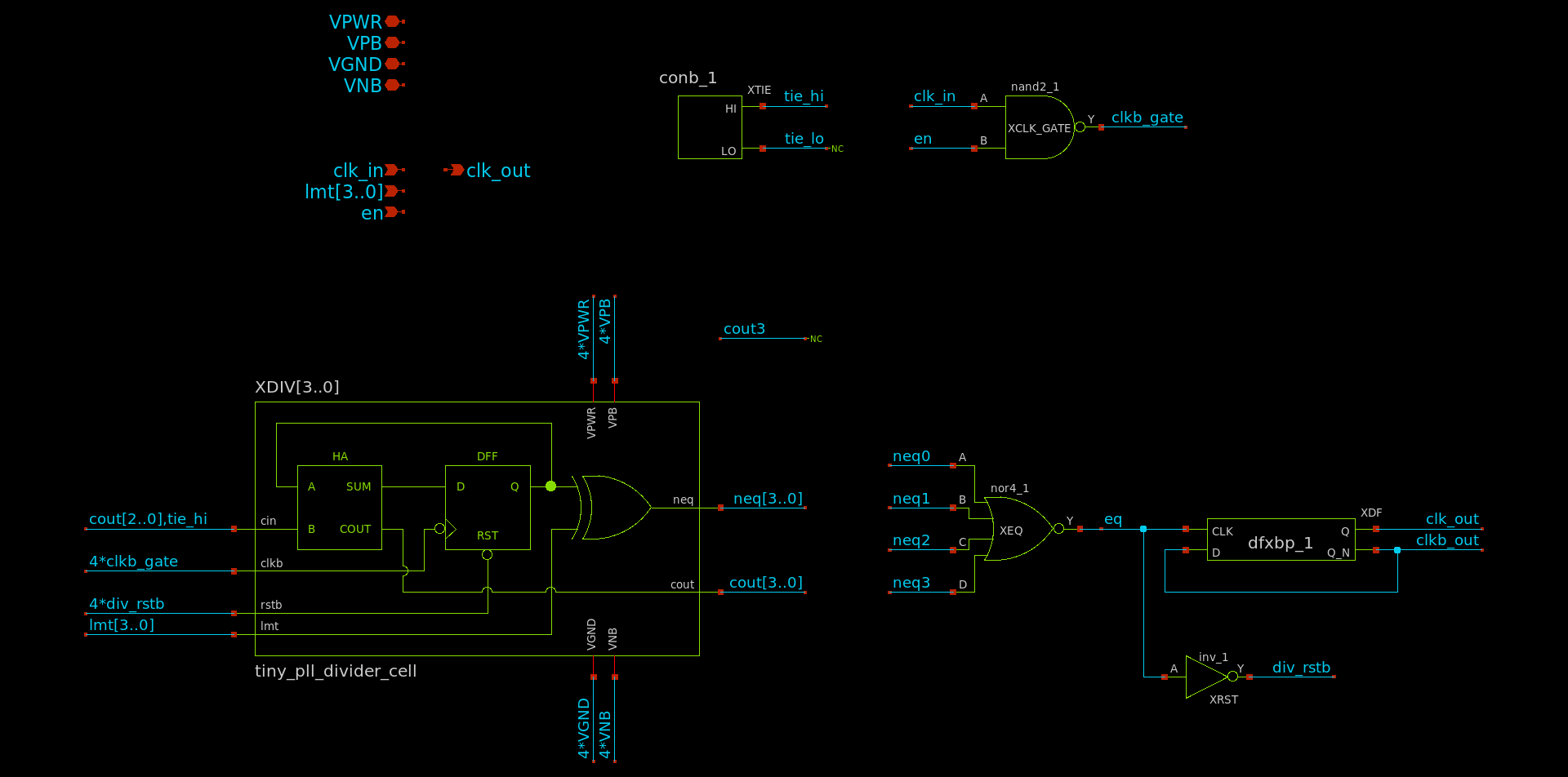

Divider

Frequency dividers are implemented using a 4-bit binary counter followed by 4

XOR gates to check for equality with a division ratio input lmt[3..0]. When

the counter output is equal to lmt, div_rstb is immediately asserted, which

resets the counter to 0 at the rising edge of clk_in. As a result, the maximum

division ratio from clk_in to eq is 15, when lmt == 4'b1111.

Since the counter is reset as soon as its output is equal to the division ratio,

a very short pulse is produced at the eq node, with a duration equal to the

propagation delay of the counter. This could potentially be a timing concern for

XDF, but since the counter delay is at least 3 gate delays, the flip-flop was

observed to operate as intended across process, voltage and temperature (PVT) in

simulation.

The D flip-flop (DFF) at the output is included to ensure an output duty cycle

close to 50%. As a result, the actual output frequency is f_ref / (2*lmt),

which implies a division ratio from clk_in to clk_out between 2 and 30.

The tie cell sky130_fd_sc_hd__conb_1 is used when gates must be connected to

VPWR or VGND to avoid potential ESD issues.

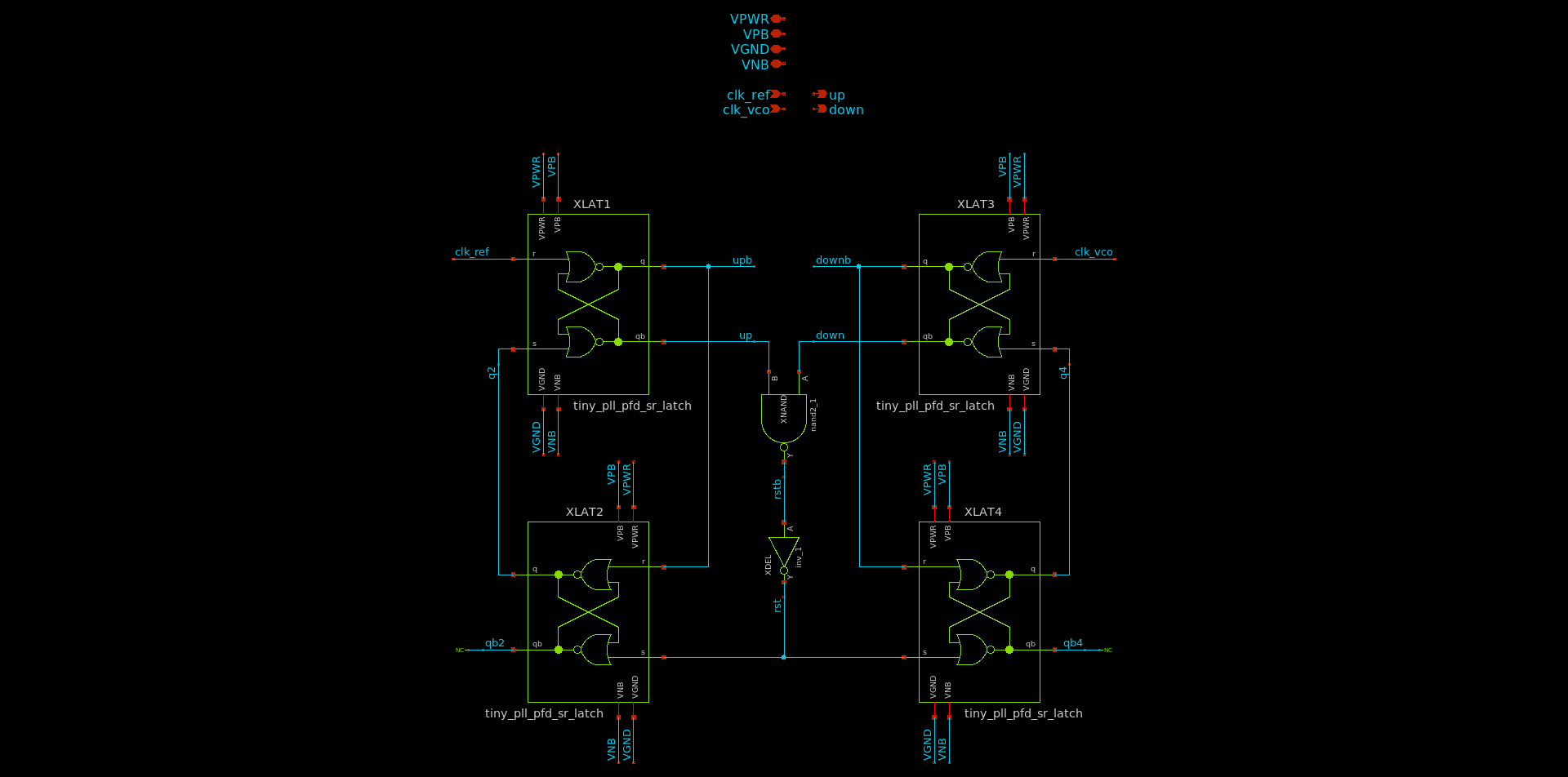

Phase-frequency detector (PFD)

The PFD is composed of two DFFs, clocked by the divided VCO output and the

reference input, respectively. Since the input of both DFFs is tied to 1, each

DFF can be implemented using two S-R latches, each of which uses two nor2

gates. The full PFD thus uses 8 nor2 gates, one nand2 and one inv_1, which

is considerably smaller than using discrete DFF standard cells with the D inputs

tied to VPWR.

A NAND followed by an inverter is used instead of a single AND to slightly increase the minimum output pulse width and avoid charge pump glitches.

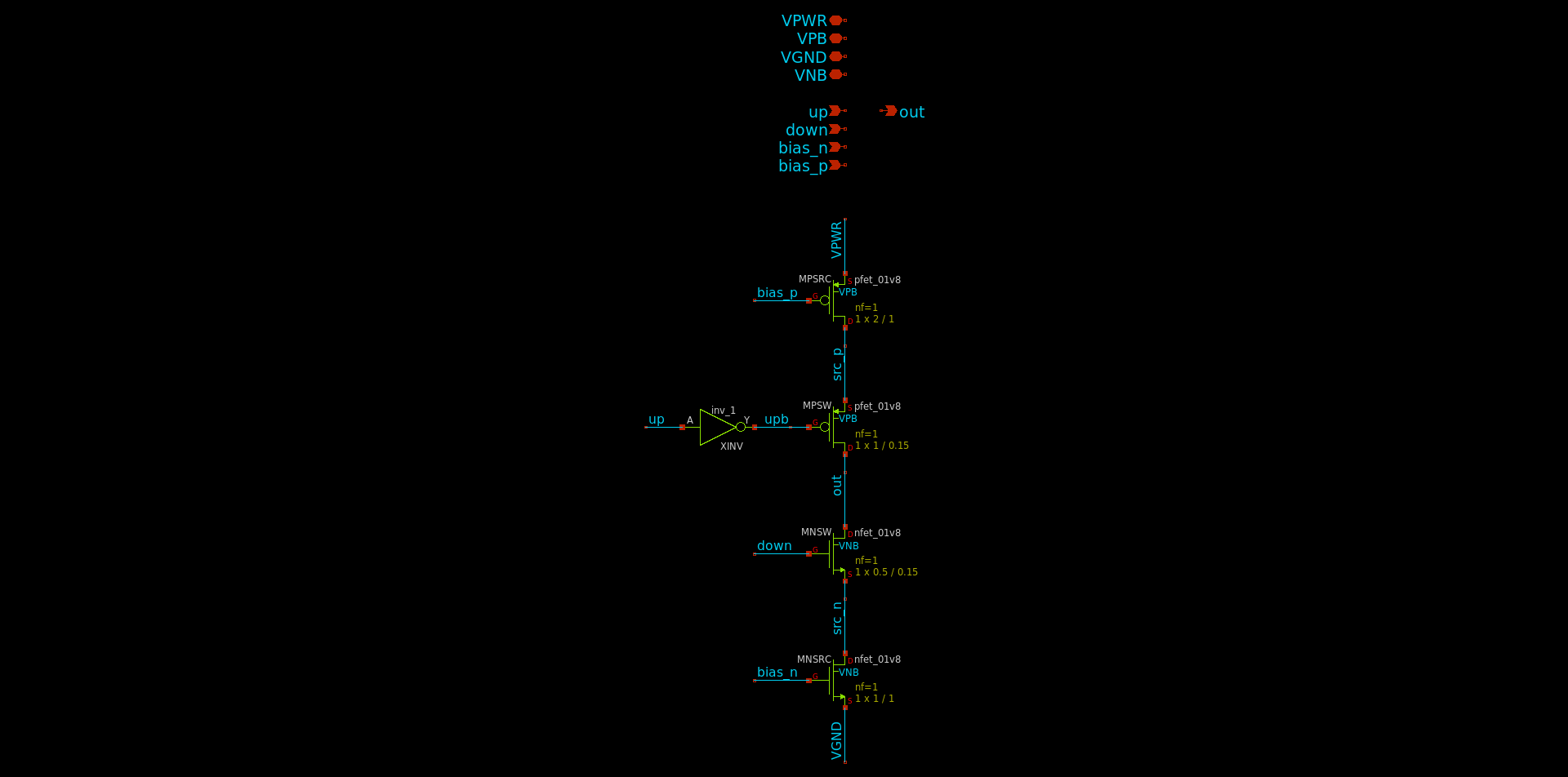

Charge pump

The charge pump uses two current sources (MNSRC and MPSRC), which can be

interchangeably switched to the output with the up and down inputs. The

charge pump current is nominally 1 uA and is set by the bias generator. The

switches use nearly minimum width to reduce area, and minimum length to reduce

capacitance. The PMOS switch uses 2x the W/L of the NMOS switch to ensure

roughly equal drain-source saturation voltages (VDSAT).

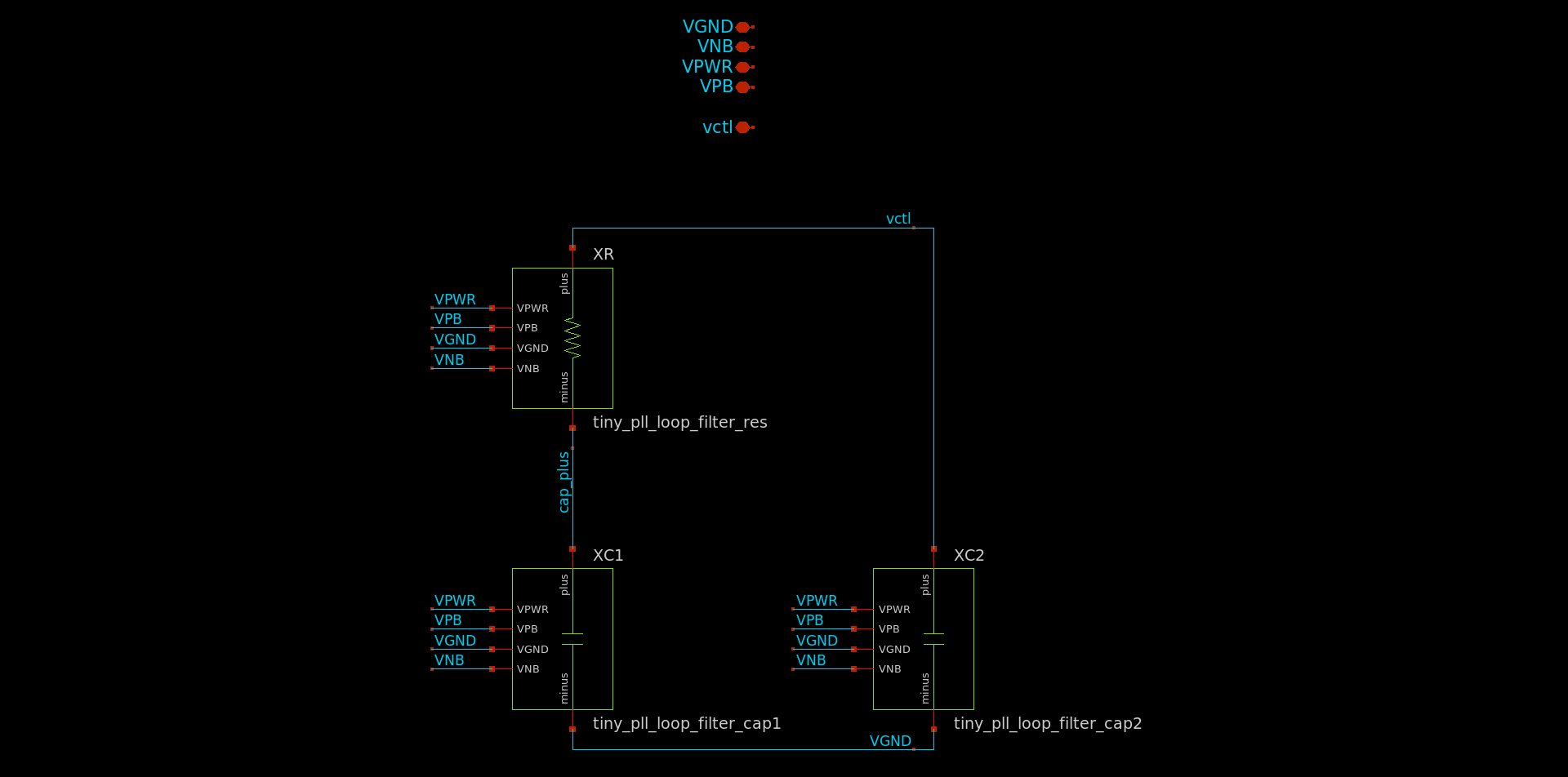

Loop filter

The loop filter is implemented using a series R/C combination to compensate the

loop transfer function such that a zero is placed below the crossover frequency

to ensure stability, and a pole is placed above the crossover frequency to

ensure fast settling time. A second capacitor XC2 is included to reduce ripple

in the control voltage, which in turn reduces phase noise at the PLL output.

Component values were selected using a linearized model developed using

schematic-only simulations of the VCO to determine the voltage-to-frequency

gain. The loop bandwidth was chosen to be on the order of 100 kHz, with a phase

margin of 65 degrees at an output frequency of 10 MHz. The resulting R/C values

are R = 100 kOhm and C1 = 1 pF.

In reality, the loop characteristics vary significantly across output frequency due to the nonlinear gain of the VCO, which was observed to have a nearly exponential voltage-to-frequency characteristic in simulation. This is likely due to the VCO current sources operating in the subthreshold region, where the ID/VGS characteristic is near-exponential.

The loop filter resistor is implemented using the urpm high-resistance poly

implant, which is roughly 2 kOhm/square. While e-test values are not provided

for this resistor in sky130, the value is not critical, and significant

variations (+/-50%) were observed to result in a stable loop in simulation.

The loop filter capacitors are implemented using NMOS devices with drain and source shorted to VGND. This is due to the significantly higher capacitance density of MOS devices relative to MIM capacitors (~8 vs ~2 fF/um^2). The MOS capacitance is highly nonlinear and increases at high control voltages due to the inversion charge, but again the capacitor value is not critical and this nonlinearity does not cause instability in the feedback loop.

The loop filter consumes nearly 50% of the area of the PLL. Various methods were explored to reduce loop filter area, including:

- MIM capacitors could be used and placed on top of the other circuit blocks to reduce area

- A capacitance multiplier could be used to allow a smaller intrinsic capacitance

The MIM capacitor method is possible, but there is some ambiguity in the

sky130 design rules as to whether a MIM capacitor can be placed over met1

and the base layers (see capm.10 in the sky130 periphery

rules.

Additionally, this could result in unwanted noise from the digital blocks

coupling into the capacitors, which could degrade phase noise performance.

Further, the capacitors would have to be divided up to lie between the power

rails on met4 which would increase their area.

A capacitance multiplier was implemented using a 100 fF capacitor with a 10:1 multiplication ratio, but the final layout was the same size as the MOS capacitor implementation and was thus exlcuded from the final design. The capacitance multiplier was additionally seen to have poor high-frequency response compared to a MOS or MIM capacitor, which resulted in unacceptably high control voltage ripple.

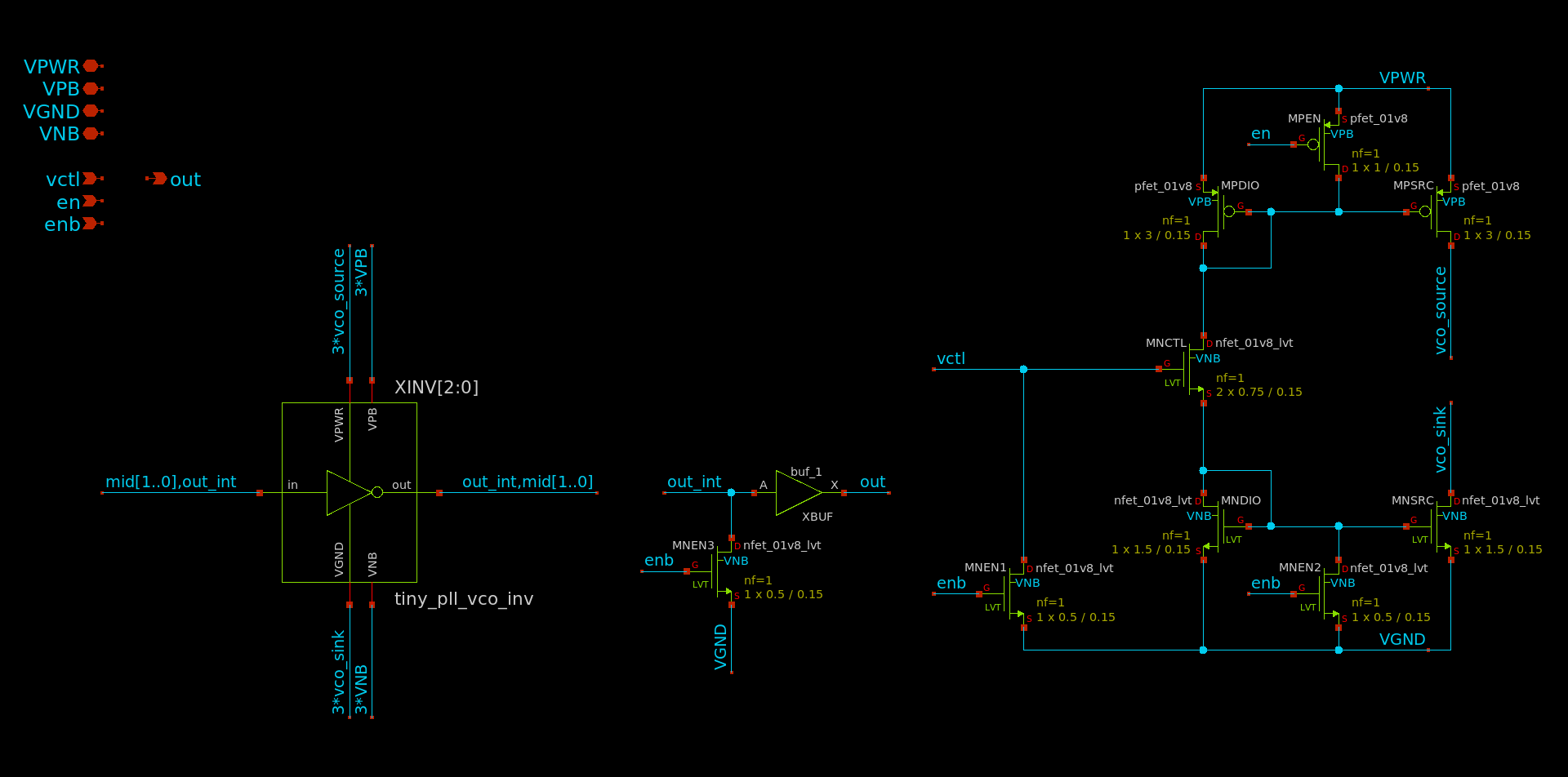

Voltage-controlled oscillator (VCO)

The VCO is a 3-stage current-starved ring oscillator using standard cell

inverters. The current sources are minimum-length to maximize W/L, which in turn

minimizes VDSAT, and minimize capacitance. The output resistance of these

current sources is irrelevant since it only matters that the oscillator current

is limited, and not the particular limit value. A triode device MNCTL is used

to control the source/sink current of the VCO. LVT NMOS devices are used to

ensure the operating control voltage is somewhere near half supply at an output

frequency of 10 MHz, which helps ensure the maximum output frequency can be met

across process variations. Four "keeper" devices (MNEN1, MNEN2, MNEN3 and

MPEN) are included to disable the circuit with zero static power consumption.

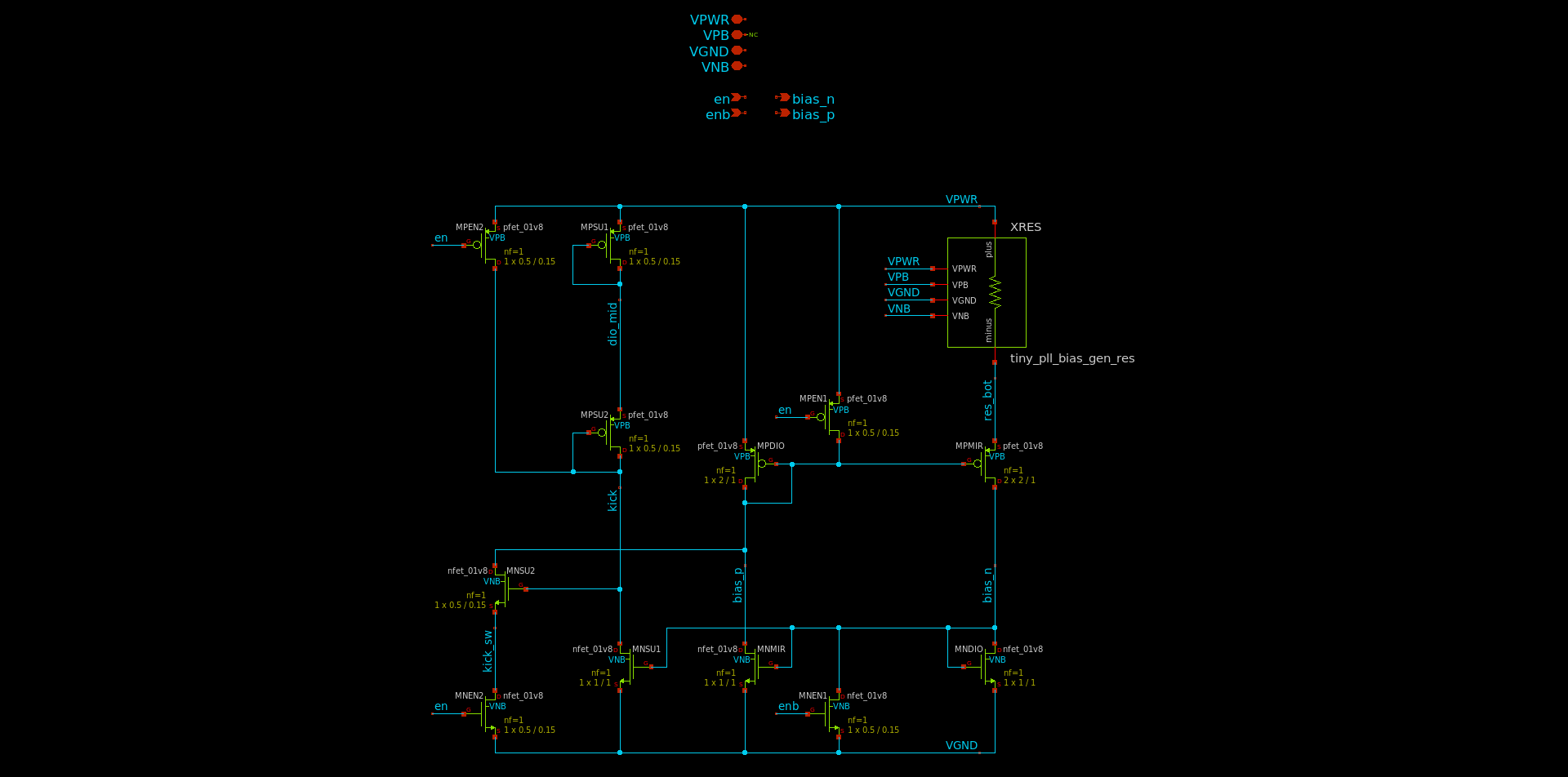

Bias generator

The bias generator is a self-biased current mirror, which provides a roughly

supply-independent current for the charge pump. The exact current is highly

dependent on the poly resistor XRES, but is designed to be nominally 1 uA at

25 degrees C. A startup circuit is included to ensure the bias generator does

not fall into an undesirable operating point where IOUT = 0. The diode devices

MPSU1 and MPSU2 charge the kick node to VPWR when the circuit is enabled,

which pulls bias_p low and establishes a current in the mirror devices. Once

the mirror is active, MNSU1 pulls kick low and disables the startup circuit.

Multiple "keeper" devices are included to disable the circuit with zero static

power consumption.

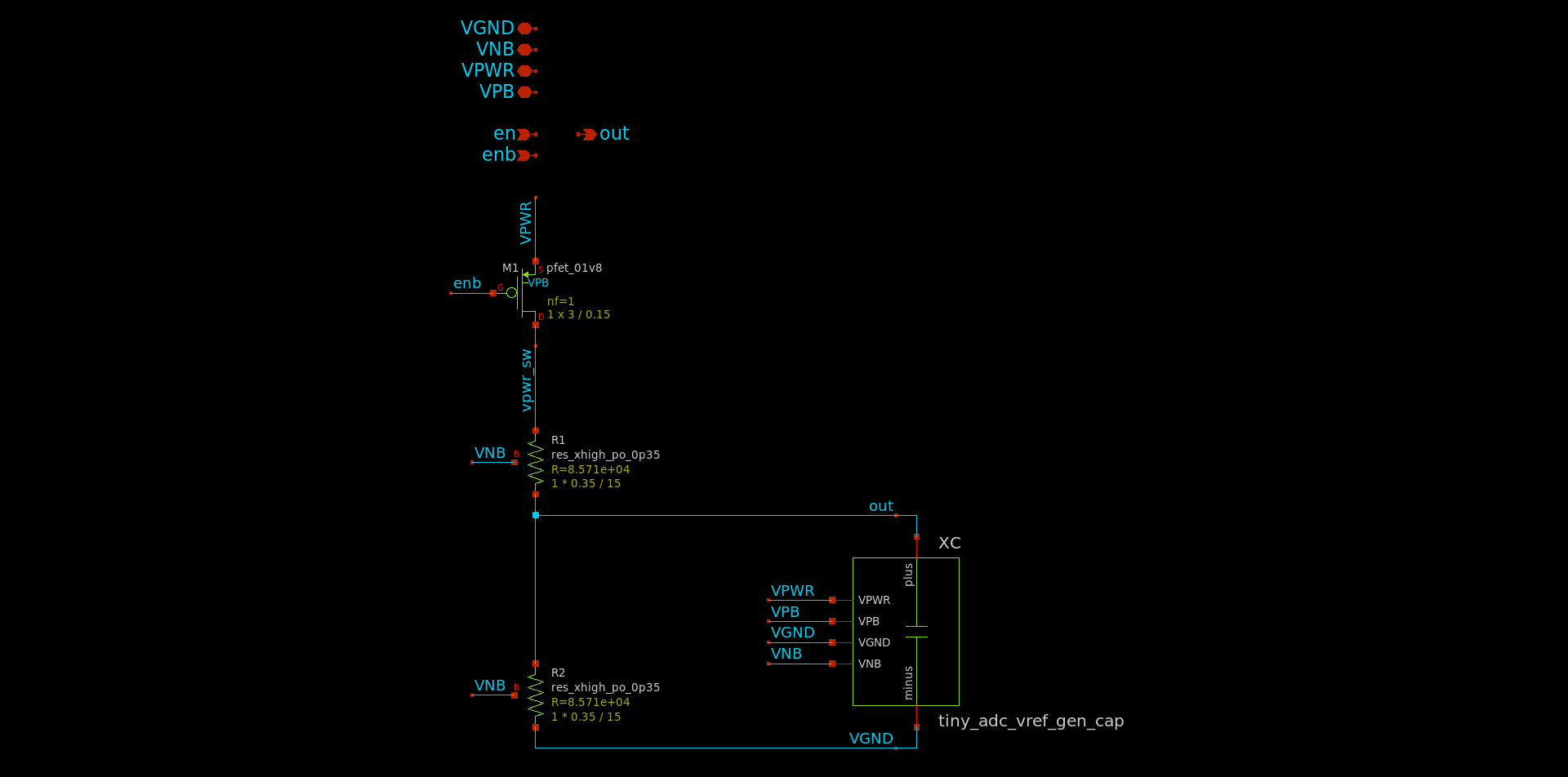

ADC

tiny_adc is a 1-bit, continuous-time, delta-sigma ADC. It is used to monitor

the control voltage of one of the tiny_pll instances without consuming an

analog I/O pin. This is useful to measure lock time and loop stability. The

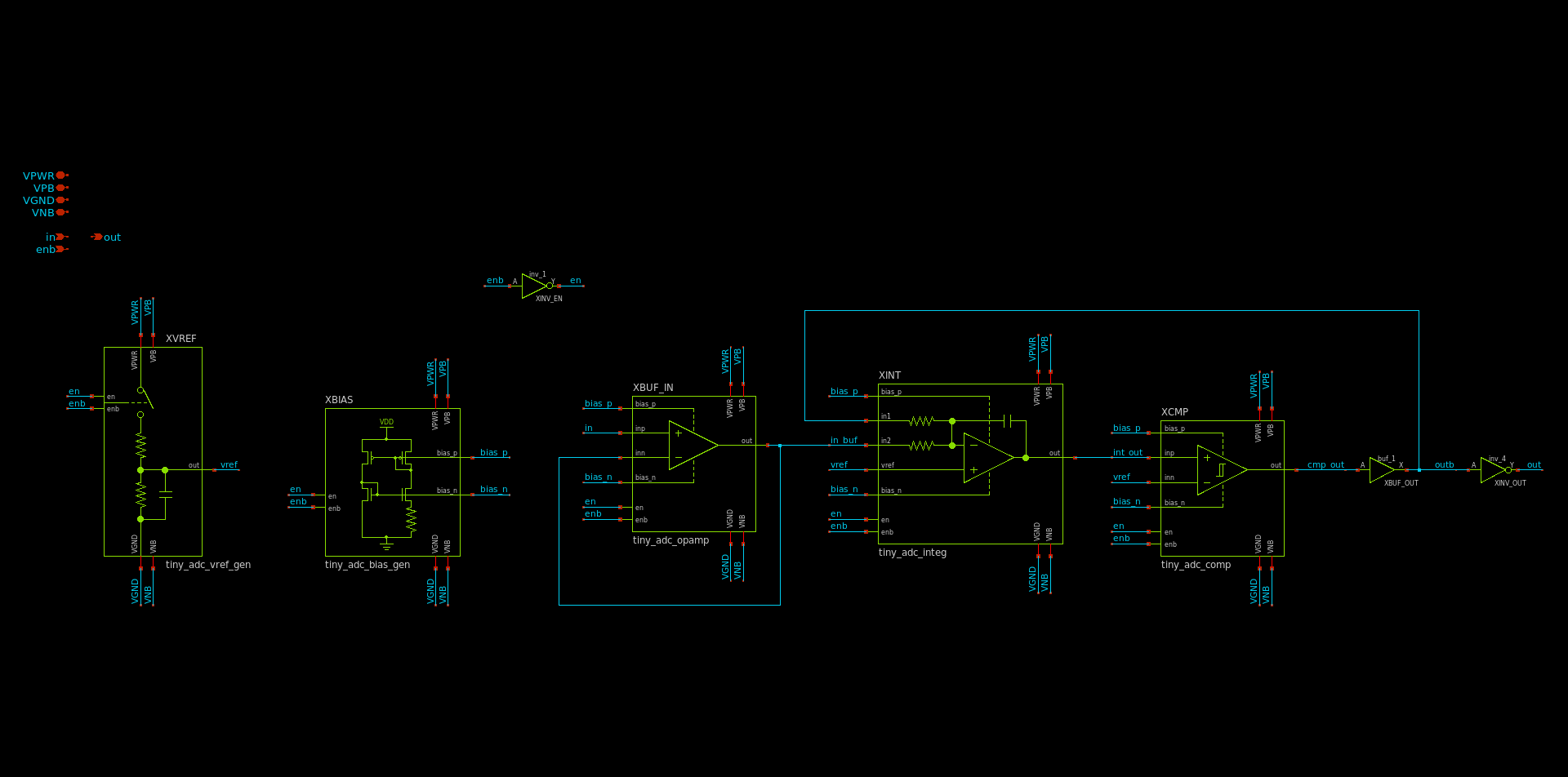

top-level schematic of tiny_adc is shown below:

XBUF_IN is a unity-gain input buffer used to eliminate DC currents into the

ADC input, which would disturb the PLL loop response. XINT is a

continuous-time integrator which accumulates the error between the analog input

and digital output. XCMP is a comparator used to resolve the integrator output

to a digital signal. Hysteresis is included to ensure a repeatable minimum pulse

width. The comparator output is buffered by XBUF_OUT to ensure fast edge

rates. A final inversion by XINV_OUT is required to cancel the negative gain

of the integrator. A reference voltage for the comparator is provided using a

simple voltage divider with included bypass capacitance. A roughly

temperature-independent 1 uA bias current is created by XBIAS, which is used

in the opamps and comparators.

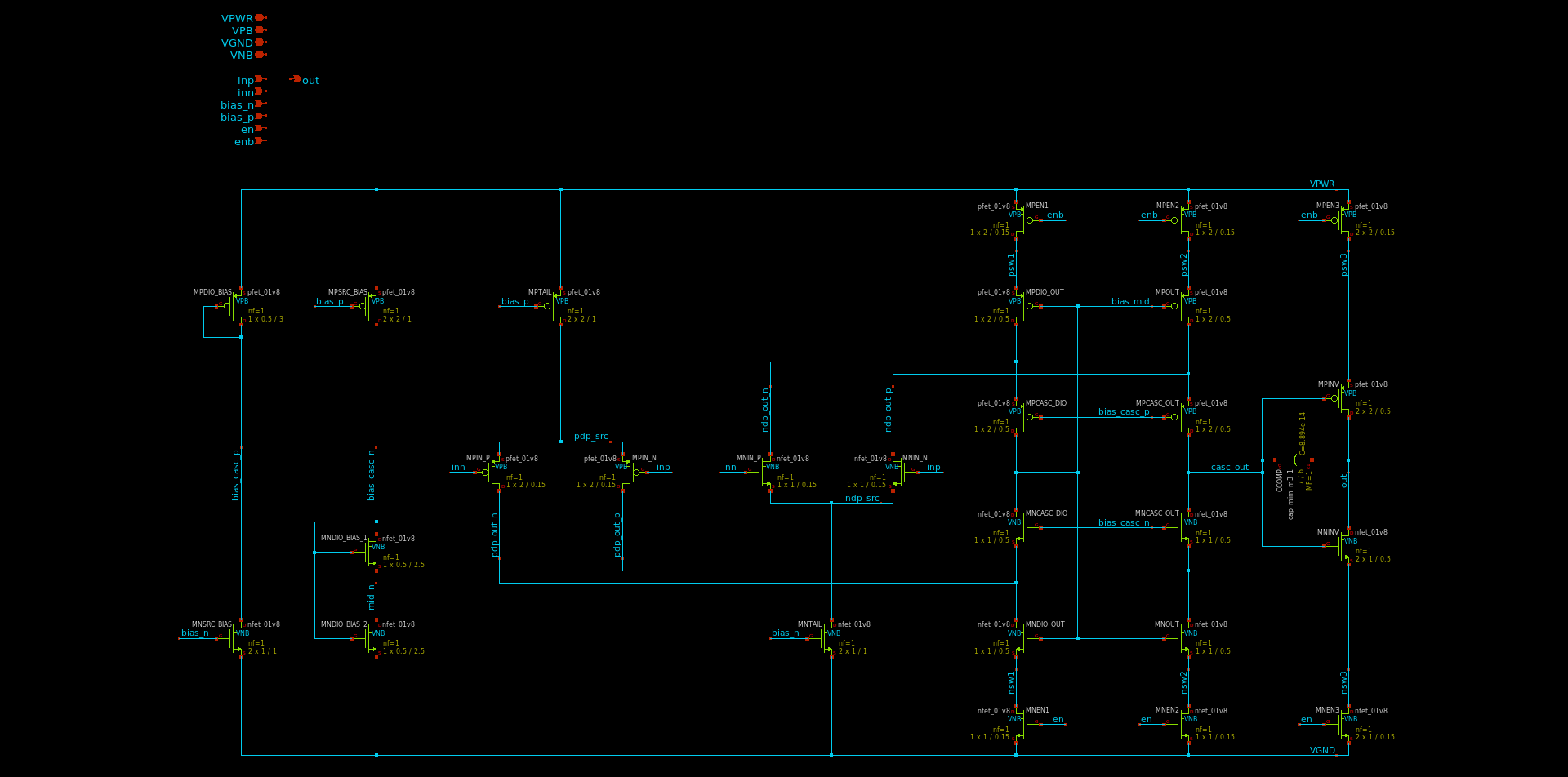

Opamp

tiny_adc_opamp is a two-stage, folded-cascode operational amplifier with

rail-to-rail inputs and outputs. Complementary NMOS and PMOS input stages

provide an input common-mode range within ~50 mV of each supply, and an inverter

is used as the output stage to provide similar swing at the output. Frequency

compensation is achieved using a MIM capacitor. Bias voltages for the cascode

devices are generated using diode-connected devices. NMOS diodes are used for

the NMOS devices, and similarly for the PMOS devices, to ensure a roughly

constant VDS across process corners. The NMOS diode is split into two series

devices to reduce area. An enable input is provided to power down the opamp with

zero static power consumption.

The tail current sources MNTAIL and MPTAIL are sized to match the devices in

the bias generator, which in turn use a 1 uM channel length for high output

resistance without the use of a cascode. The input devices MNIN* and MPIN*

are minimum-length to reduce input capacitance and decrease VDSAT, which results

from the high W/L. The output resistance of these devices is irrelevant since

they drive a low-impedance load at the input to the cascode stage. The cascode

and inverter stages use L = 0.5 to ensure high gain while keeping devices

small. All enable/disable switches use minimum length to reduce area.

Bias current for the input devices is set by the bias generator, which sets a

roughly 2 uA current for each differential pair, or 1 uA per input device. To

avoid the need for additional bias generators, the cascode and output stages are

self-biased. The diode-connected devices MNDIO_OUT and MPDIO_OUT appear in

series across the supply rails and set a roughly 2 uA current for MNDIO_OUT,

MNOUT, MPDIO_OUT and MPOUT. Accordingly, the cascode devices M*CASC*

each carry the difference in current between the input devices and the

diode-connected devices in the cascode stage, i.e., roughly 1 uA. The bias

current of the output stage varies with output voltage but peaks at roughly 10

uA near mid-supply.

The compensation capacitor was chosen to yield a 65 degree phase margin with a

10 fF load capacitance and VOUT = 0.9 V. The actual phase margin varies by

output voltage due to the nonlinear output stage, with higher phase margin near

either supply rail due to the decreased gain of the output stage. The phase

margin was found to be degraded to roughly 55 degrees following parasitic

extraction. The in-circuit phase margin is likely larger than this, however,

since the 10 fF load estimate should be quite conservative. The input buffer

amplifier drives a high-impedance load, meaning that the only purely capacitive

load at its output is due to wiring parasitics over a fairly short distance. The

integrator only drives the input of the comparator, which uses minimum-length

devices with 1-2 fF of gate capacitance each.

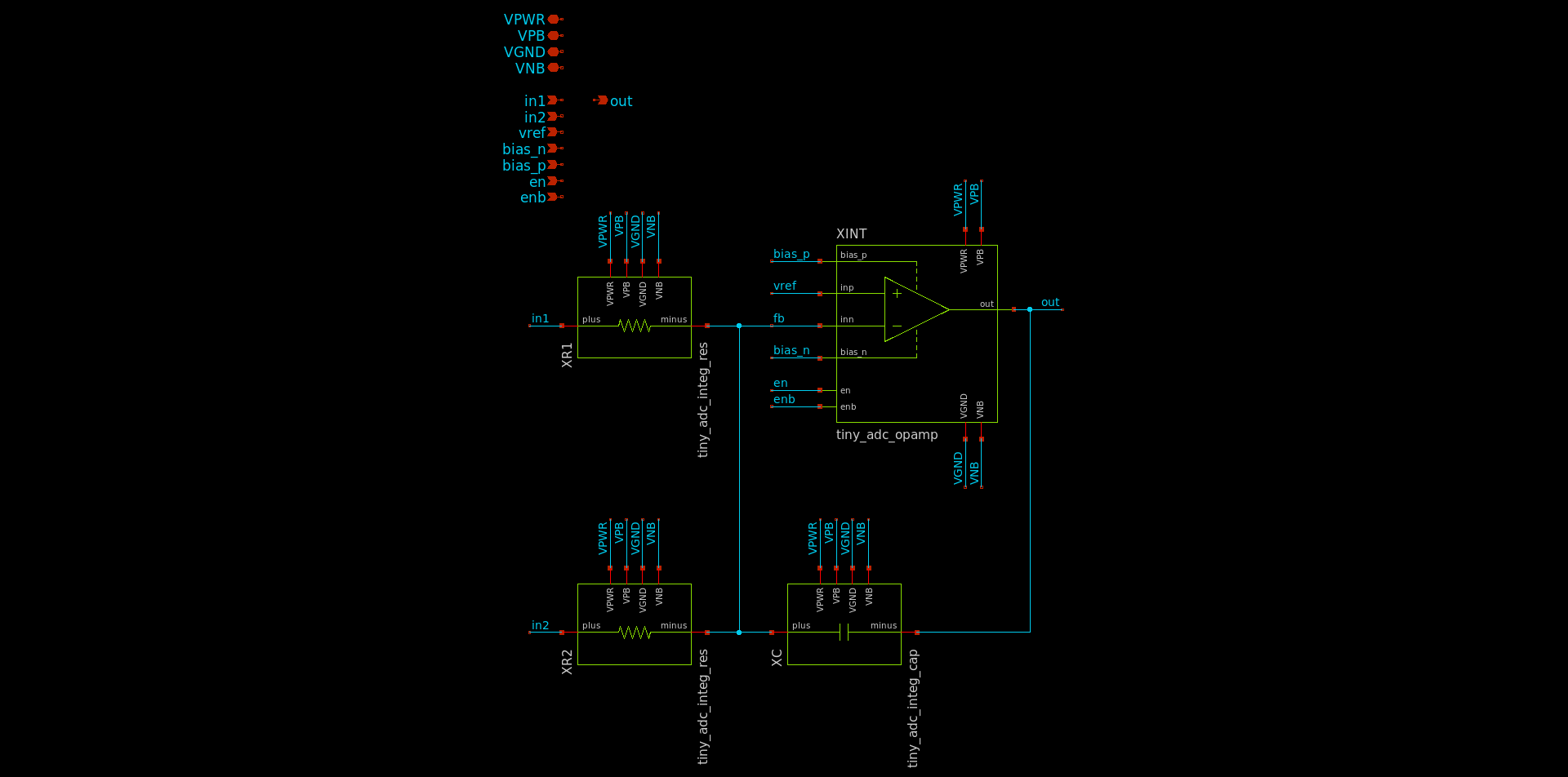

Integrator

The integrator uses tiny_adc_opamp with two sky130_fd_pr__res_xhigh_po_0p35

resistors and one MIM capacitor. The resistors are roughly 500 kOhm each, and

the capacitor is 100 fF. Component values were chosen to ensure the minimum

output pulse width is long enough to be accurately reproduced by the Tiny

Tapeout mux and I/O cells. The minimum pulse width is approximately R*C*Vh / VDD, where Vh is the hysteresis of the comparator. If Vh = 1 V, VDD = 1.8 V, R = 500 kOhm and C = 100 fF, the minimum pulse width is roughly 28 ns.

Tiny Tapeout uses the sky130_ef_io_gpiov2_pad cell for I/O, which is specified

for a maximum output frequency of 33 MHz. As this implies a pulse width of 15

ns, the 28 ns pulse width used here should be comfortably within the limits of

the I/O cells.

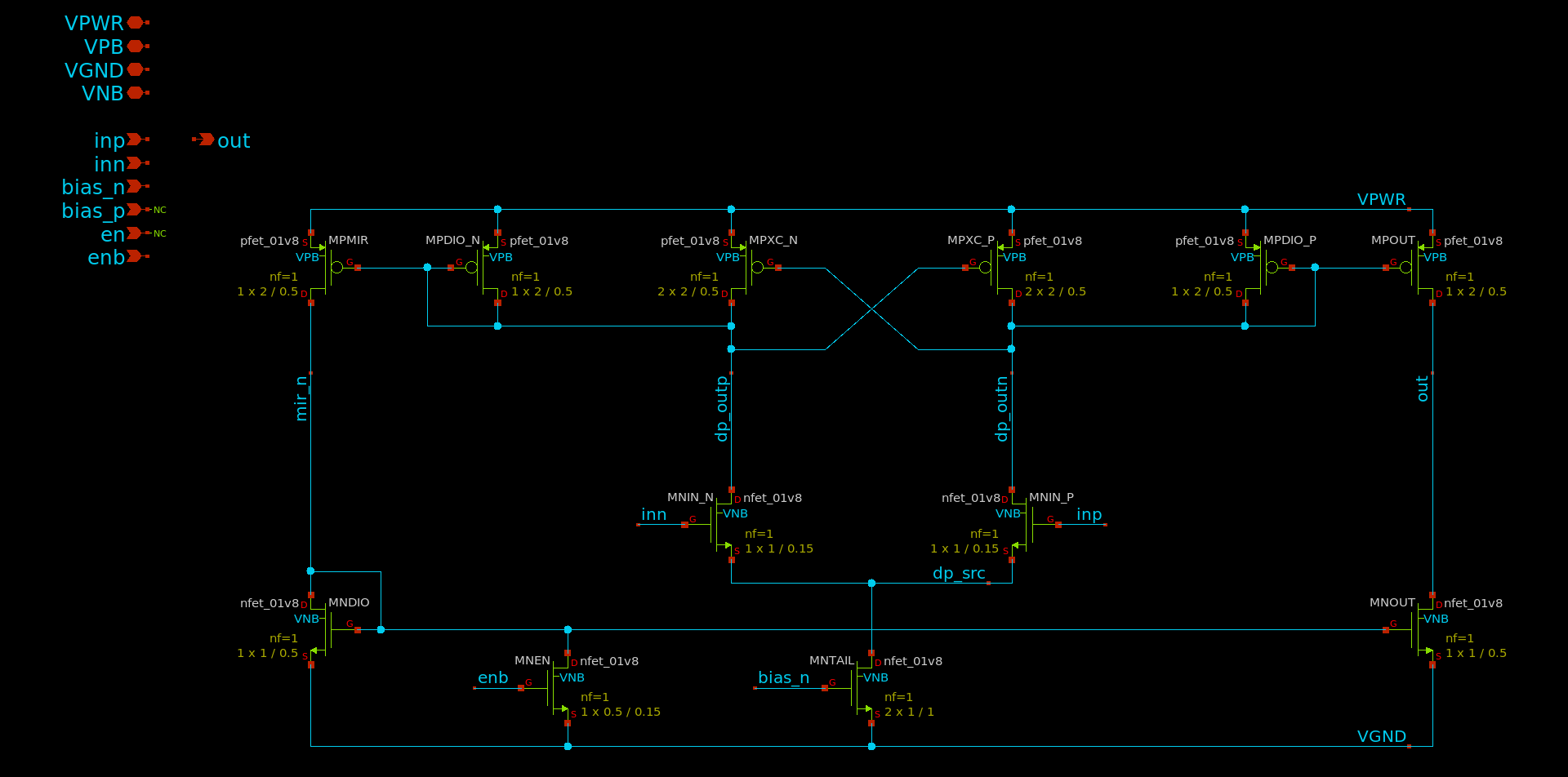

Comparator

tiny_adc_comp is a two-stage comparator using a current mirror architecture,

with cross-coupled PMOS devices used to add hysteresis. The amount of hysteresis

is controlled by the ratio of the W/L of the cross-coupled devices to that of

the diode-connected PMOS devices. Denoting this ratio as r, the current in one

branch of the input differential pair must exceed that in the other branch by a

factor of r to cause the output to change states. Thus, we must have r > 1

to ensure hysteresis. In this design, r = 2 was found to result in a

hysteresis of roughly 1 V in simulation. To ensure a similar slew rate to that

of the opamp, a 2 uA tail current was chosen, which is generated by the bias

generator.

Bias generator

The bias generator is based on rburt's TT08

submission. The design

has been modified to use smaller devices and provide an enable/disable

functionality using "keeper" devices. Compared to rburt's design, this design

exhibits a greater temperature dependence since the devices operate closer to

inversion due to the lower W/L. Still, the bias current was found to vary by

approximately 10% from 0 to 100 Celsius, which is acceptable for tiny_adc

since the bias current is not critical.

A different startup circuit is also used to minimize area consumption. This

startup circuit relies on the kick node being precharged to VPWR when the

circuit is enabled. As a result, en must be brought low for a short time by

the control logic prior to enabling the circuit. This can be accomplished by

asserting rst_n at the top level, then writing 4'b0000 to CSR address

4'h8, since the default state of the CSRs disables all the PLLs after rst_n

is asserted.

Reference voltage generator

The reference voltage generator is a simple voltage divider with integrated

bypass capacitor. The bypass capacitor uses large NMOS devices with drain and

source shorted to VGND to save area due to the higher capacitance density

relative to MIM or MOM capacitors in sky130. The voltage divider resistors are

nominally 100 kOhm each, resulting in a roughly 10 uA bias current through the

divider. The implied bandwidth of the RC filter is 32 MHz. A power switch is

included to allow the circuit to be powered down with zero static power

consumption.

Simulation results

This section details simulation results for tt_um_tiny_pll. Due to time

constraints, not every block was simulated across PVT corners. Consequently,

results are only reported here at the TT process corner with VDD = 1.8 V and

T = 27 C.

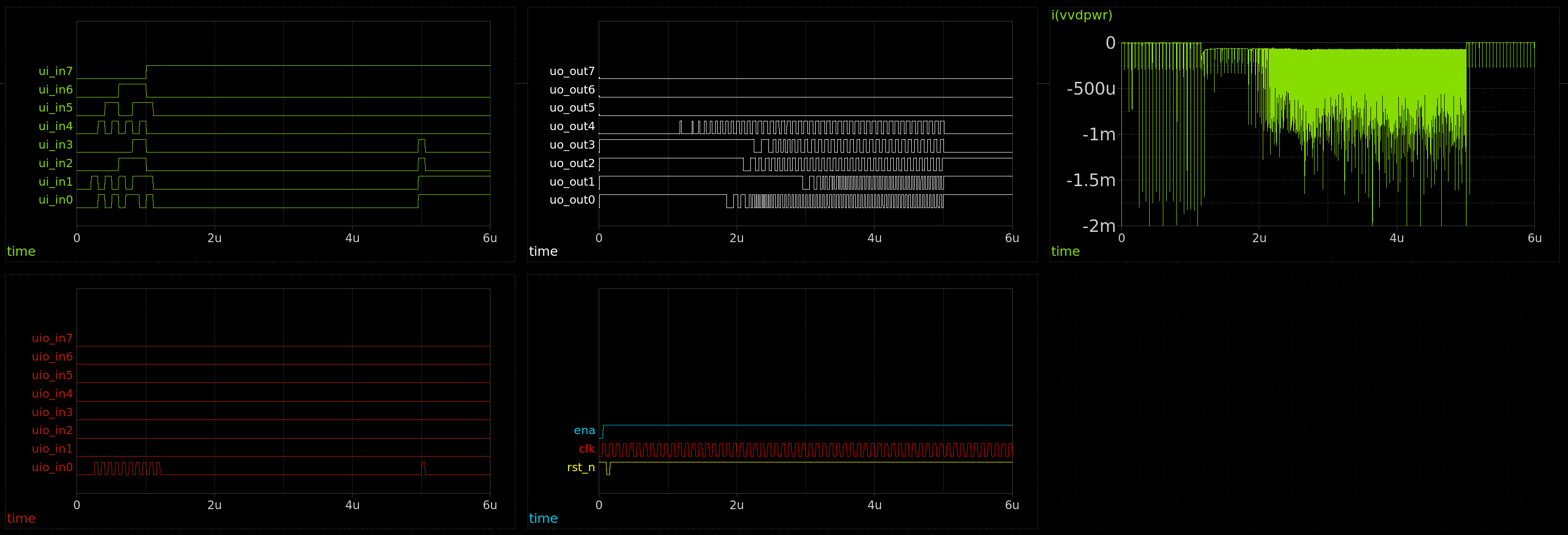

Top level

To verify top-level functionality, a simulation was performed of the full Tiny Tapeout tile using extracted parasitics. The netlist used for this simulation can be found here. The final instance count in the extracted netlist is shown below:

| Cell | Instances |

|---|---|

sky130_fd_pr__nfet_01v8 |

2,964 |

sky130_fd_pr__nfet_01v8_lvt |

28 |

sky130_fd_pr__special_nfet_01v8 |

328 |

sky130_fd_pr__pfet_01v8 |

97 |

sky130_fd_pr__pfet_01v8_hvt |

3,176 |

sky130_fd_pr__res_xhigh_po_0p35 |

26 |

sky130_fd_pr__res_generic_po |

54 |

sky130_fd_pr__cap_mim_m3_1 |

3 |

r |

94,481 |

c |

50,817 |

A large number of the nfet_01v8 and pfet_01v8_hvt devices are located in the

decap cells placed by the OpenROAD flow. The results of the top-level simulation

are shown below:

The testbench performs the following steps:

- Asserts

ena - Asserts

rst_nfor 50 ns to initialize CSRs - Sets the multiplication ratio for channel 0 to 2/1

- Sets the multiplication ratio for channel 1 to 2/1

- Sets the multiplication ratio for channel 2 to 6/5

- Sets the multiplication ratio for channel 3 to 15/14

- Sets the reference source of channel 1 to the output of channel 3

- Enables all 4 channels

- Disables all 4 channels at

t = 5 usto test powerdown functionality

The CSR values are clocked in at 10 MHz using the CSR clock input at

uio_in[0].

As seen in the waveform plots above, lock is achieved for channels 0, 1 and 3

within 2 us, with an additional ~1us for channel 2 since its output depends on

that of channel 3. The ADC output at uo_out[4] was observed to behave as

intended, with a time-varying duty cycle corresponding to the control voltage

for PLL channel 0. Powerdown was completed successfully at t = 5 us, with DC

supply current decreased to 0. The remaining power consumption after powerdown

is caused by the input clock buffers inserted by TritonCTS during clock tree

synthesis.

Due to the large number of parasitic resistors and capacitors, the simulation

required roughly 10 hours to complete using an Intel i7-1065G7 processor with

16GB of RAM. Multithreading support was enabled, and .options klu was passed

to speed up transient simulation, as detailed in the ngspice user manual. The

testbench uses the d_source XSPICE component to generate a digital stimulus

from a csv input. This automatically sets .options trtol=1, which slows down

transient simulation by a factor of 2. To speed up simulation, PWL voltage

sources could be used to eliminate the need for XSPICE blocks. Although the

simulation speed could be increased by increasing the maximum timestep from

100ps to 1ns, this was found to result in incorrect operation of the PLL due to

the short reset pulse used by this block internally.

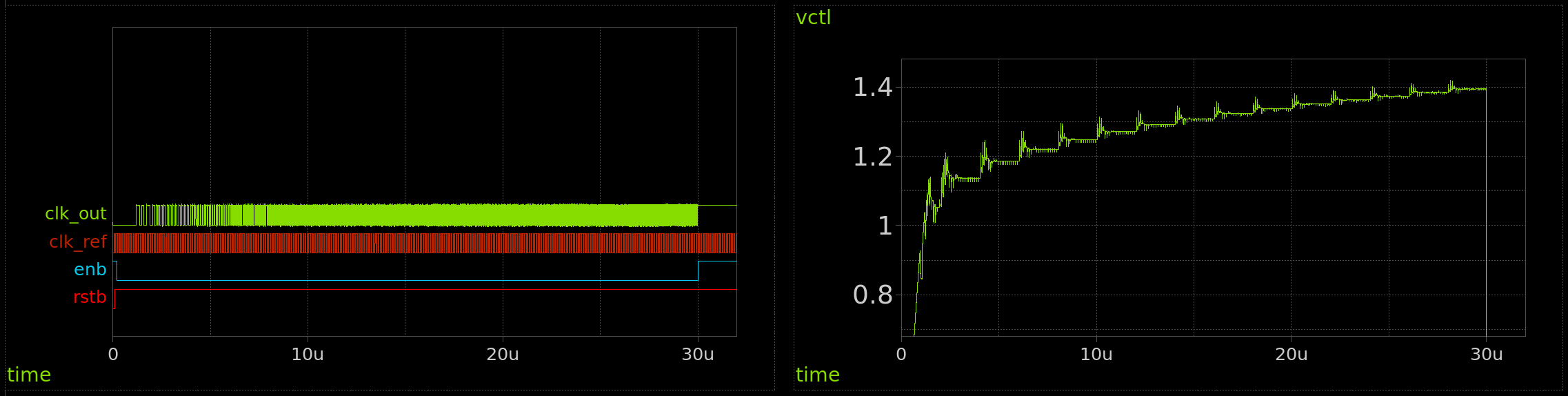

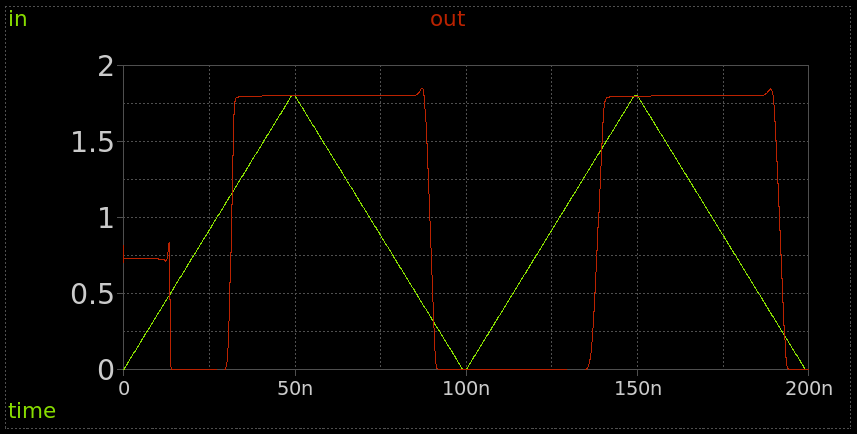

PLL

To verify functionality of the tiny_pll tile, a transient simulation was

performed using an extracted SPICE netlist. The results of this simulation are

shown below:

This testbench initializes the PLL by pulsing rstb then asserting enb. The

feedback division ratio is then swept from 1 to 15 in 2 us steps to verify

divider operation at each VCO frequency. The dividers were observed to output

the correct frequency up to the maximum output frequency of 150 MHz. Settling

time was under 2 us for all divider codes, with higher frequencies settling

slightly faster with smaller control voltage transients. This is due to the use

of MOS capacitance in the loop filter: The effective capacitance is larger at

higher VGS due to the inversion charge in the channel, which results in improved

loop dynamics relative to lower control voltages. The PLL consumes up to 200 uA

RMS when active, with higher frequencies resulting in higher current

consumption. The PLL was disabled at 30 us by deasserting enb and consumed

less than 1 uA thereafter. The power consumption in this condition is likely

dominated by leakage through the digital gates.

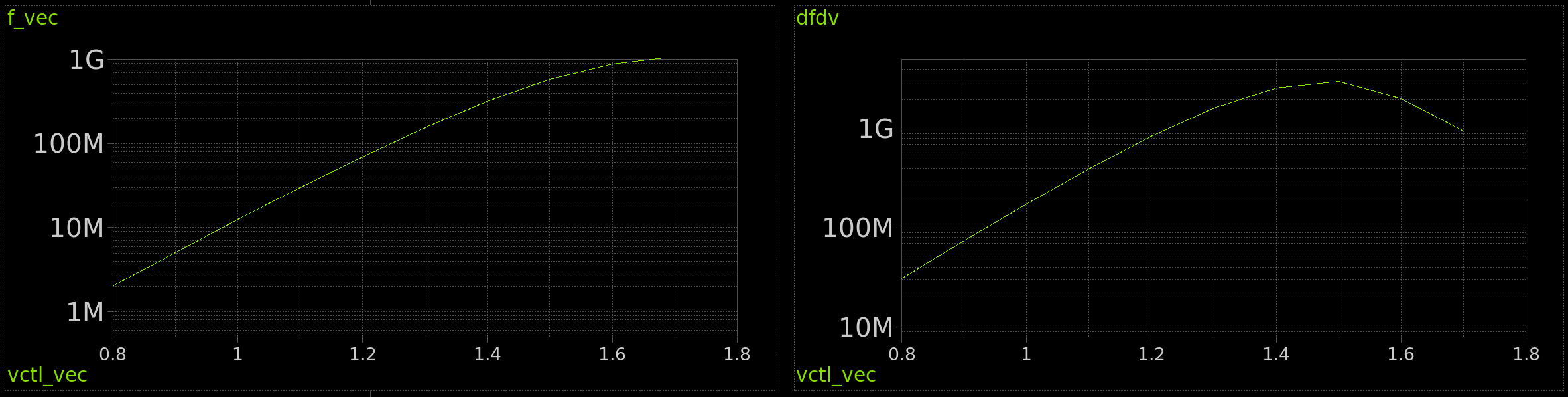

VCO

The VCO was characterized by measuring its output frequency while sweeping the

control voltage. The incremental voltage-to-frequency gain df/dV was also

computed to use in loop filter design. The results of this simulation are shown

below:

An ngspice control script was used to implement the frequency sweep. The

algorithm is roughly as follows:

- Set the control voltage to the minimum of the desired sweep range

- Run an initial transient simulation using a large, pre-determined timestep a. Stop the simulation after one cycle is completed b. Compute the timestep that would be required to yield 1,000 datapoints per cycle at the previously measured cycle period

- Run another transient simulation using the timestep determined in the previous step a. After each cycle, measure the period of the VCO output b. If the frequency has changed by more than 1% since the previous cycle, continue simulating c. If not, record the frequency and proceed to the next step

- Update the simulation timestep based on the measured output frequency

- If the control voltage sweep has not been completed, jump to step 3

This algorithm limits the length of each transient simulation to the exact

numebr of cycles that must be completed to ensure the output frequency has

settled to within 1%. This is especially helpful in reducing simulation time

when an extracted netlist is used. This is made possible by the stop command

in ngspice, which allows breakpoints to be inserted in a transient simulation.

The breakpoints are triggered when the output voltage is either greater than or

less than VPWR/2, depending on the edge direction. Since rising and falling

events are not supported, the following method was used to measure the

oscillator frequency:

- Run the simulation and stop when

vout < VPWR / 2 - Delete the previous breakpoint

- Run the simulation and stop when

vout > VPWR / 2 - Delete the previous breakpoint

- Record the current time and the time elapsed since the previous rising edge

- If needed, repeat beginning at step 1

Care must be taken to ensure the correct breakpoint is removed, since ngspice

only allows referencing breakpoints by ID, which is a counter that begins at 1

and increases with the creation of each subsequent breakpoint.

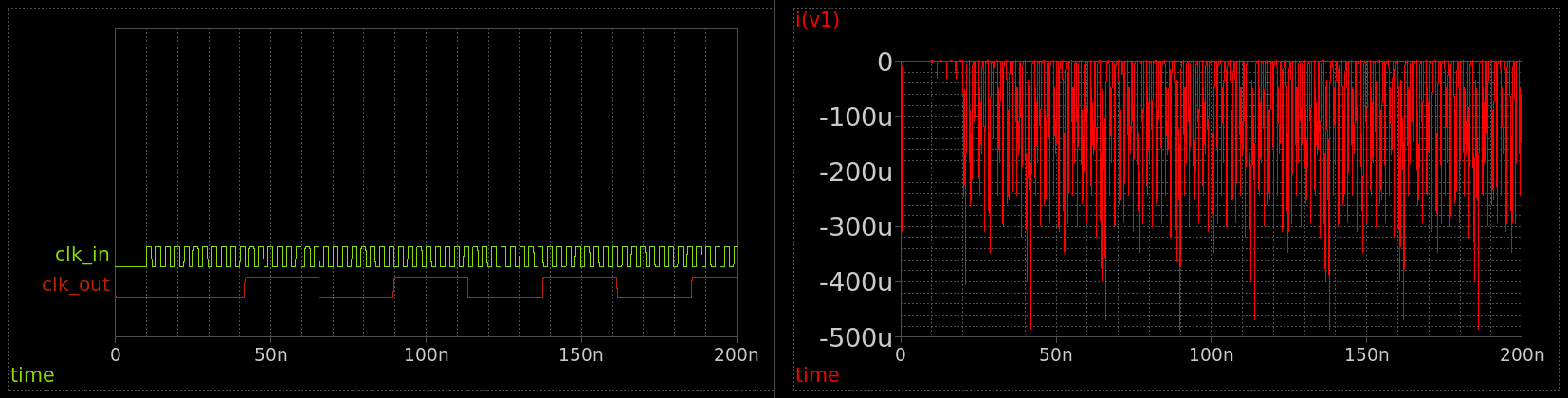

Divider

The frequency divider was simulated using an extracted netlist to ensure correct operation:

The waveforms above used lmt = 8, which results in a division ratio of 16 due

to the extra flip-flop at the output. The divider was observed to operate

correctly with an input frequency of 333 MHz, which is higher than the maximum

VCO frequency of 300 MHz. This was also verified at the SS process corner for

completeness. The supply current was roughly 120 uA with 10 fF load capacitance.

Since the layout of the feedback and output dividers is slightly different due

to asymmetry, these simulations were repeated using both extracted layouts.

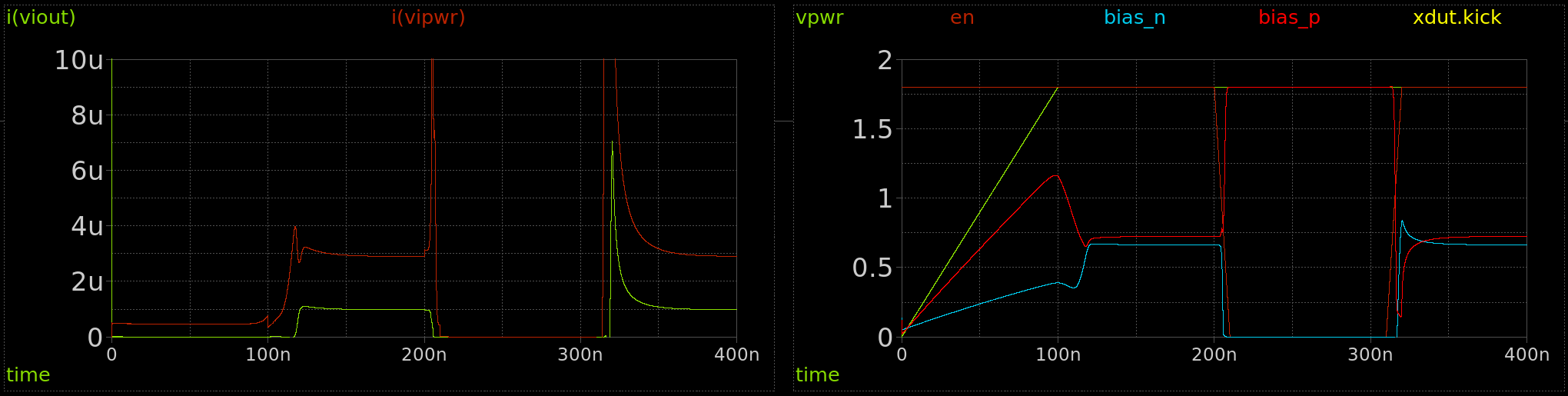

Bias generator

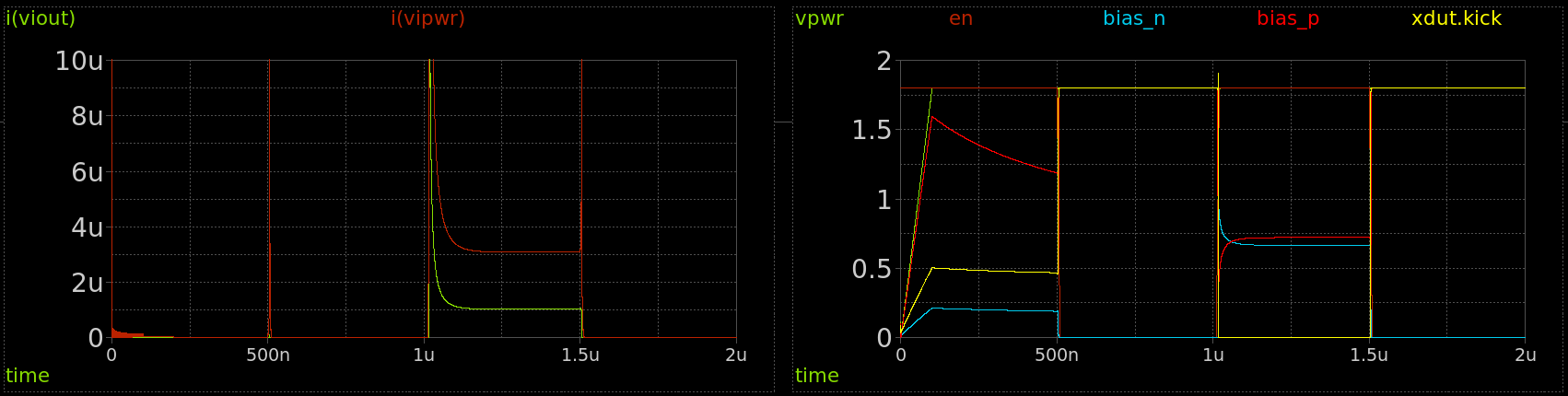

The bias generator was simulated using an extracted netlist to verify output current and startup transients:

Here, i(viout) and i(vipwr) are the output and supply currents,

respectively. As shown in the schematic above, the PMOS diode

devices MPSU1 and MPSU2 are included to charge the kick node to VPWR.

Consequently, this bias generator can start up without requiring a pulse on en

like the ADC bias generator.

The output current is nominally 1 uA but varies up to 20% across process and

temperature due to the use of the xhigh_po resistor, which has a positive

temperature coefficient. This was deemed to be acceptable for the PLL, since the

bias generator only controls the charge pump current, which results in a stable

loop even under significant variations in current. A future revision of the PLL

tile would replace this bias generator with the one used in the ADC, which does

not use a resistor, and thus offers lower variation across corners and reduced

area.

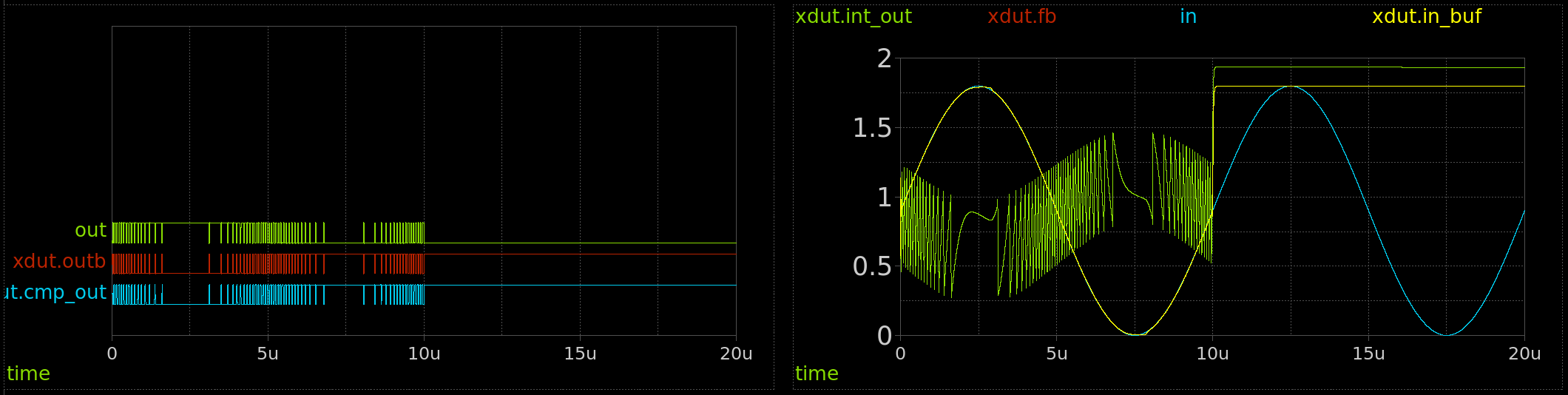

ADC

Schematic-only simulations were performed for tiny_adc to verify

functionality. Results of this simulation are shown below:

Here, a 100 kHz sine wave with 1.8 V amplitude is applied to the ADC input to

test rail-to-rail capability. The output was observed to have a time-varying

duty cycle corresponding to the instantaneous input level, as expected. The

trace xdut.in_buf is the output of the buffer opamp, which was observed to

track the input voltage to within a small distance of the positive and negative

supplies. The comparator output at xdut.cmp_out was measured to ensure the

comparator slew rate was adequate to cause the output to transition at the

minimum output pulse width.

Opamp

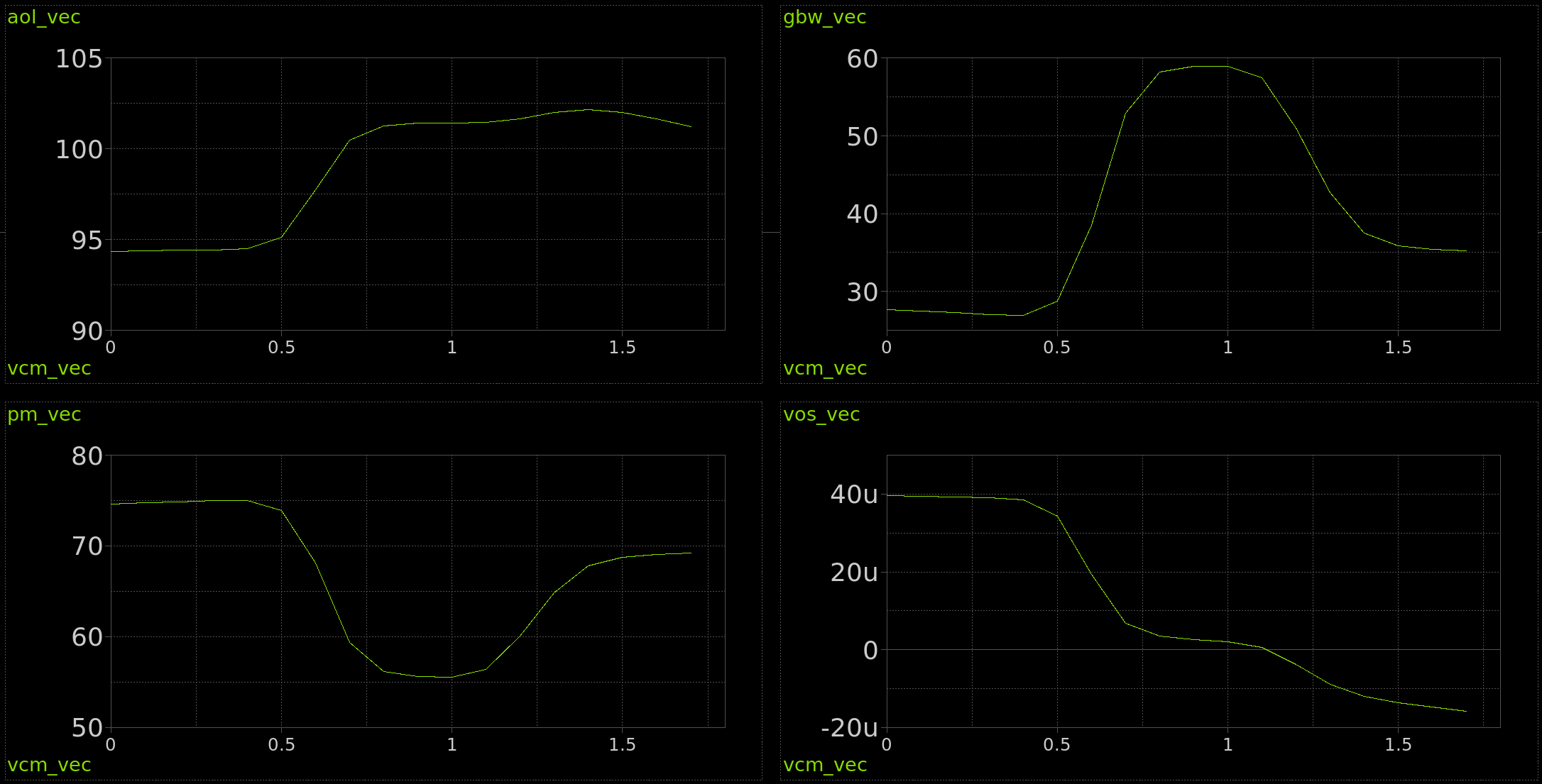

Results of an extracted simulation of tiny_adc_opamp are shown below:

Here, the common-mode voltage vcm_vec is swept from 0 V to 1.8 V, and an AC

simulation is run at each bias point. aol_vec is the open-loop gain in dB,

gbw_vec is the unity-gain bandwidth in MHz, pm_vec is the phase margin in

degrees, and vos_vec is the systematic offset voltage in V. Simulations were

performed with a load capacitance of 10 fF. The opamp exhibits a high gain

between 90 dB and 105 dB due to the two-stage architecture. The minimum phase

margin is roughly 55 degrees near a common-mode voltage of 1 V. The minimum

bandwidth of roughly 25 MHz occurs with a common-mode input near ground. The

bandwidth peaks near mid-supply, since both the NMOS and PMOS input pairs are

active in this area, leading to a higher transconductance in the input stage.

While the systematic offset is very low, Monte Carlo simulations would be

required to characterize the offset with device mismatch.

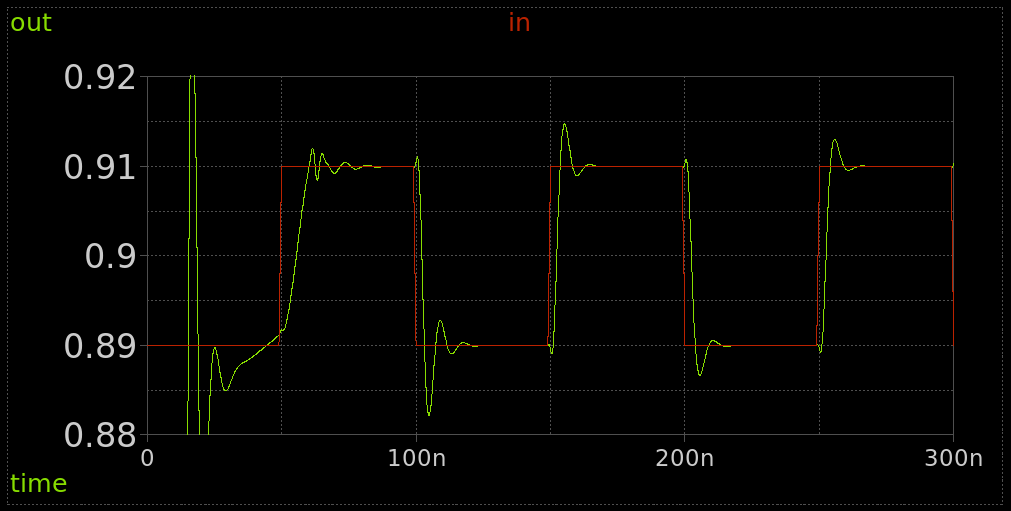

A transient simulation was also performed using the extracted netlist to verify stability under unity-gain feedback:

The simulation was performed with a load capacitance of 10 fF. Overshoot and undershoot of roughly 0.5% were observed in the small-signal step response at the worst-case common-mode input of roughly VPWR/2. This simulation is likely pessimistic relative to the in-circuit conditions, since the load capacitance seen by each opamp is likely to be less than 10 fF.

Bias generator

The ADC bias generator was simulated using an extracted netlist to verify startup behavior:

Unlike the PLL bias generator, this circuit will not start up unless en and

enb are temporarily deasserted to precharge the kick node high. While this

adds an extra requirement to the initialization sequence, it slightly reduces

area of the bias generator by avoiding the need for a resistor or diode-

connected devices to charge the kick node asynchronously. Since en is

deasserted by default when rst_n is asserted at the chip level, a short pulse

at rst_n is sufficient to ensure startup.

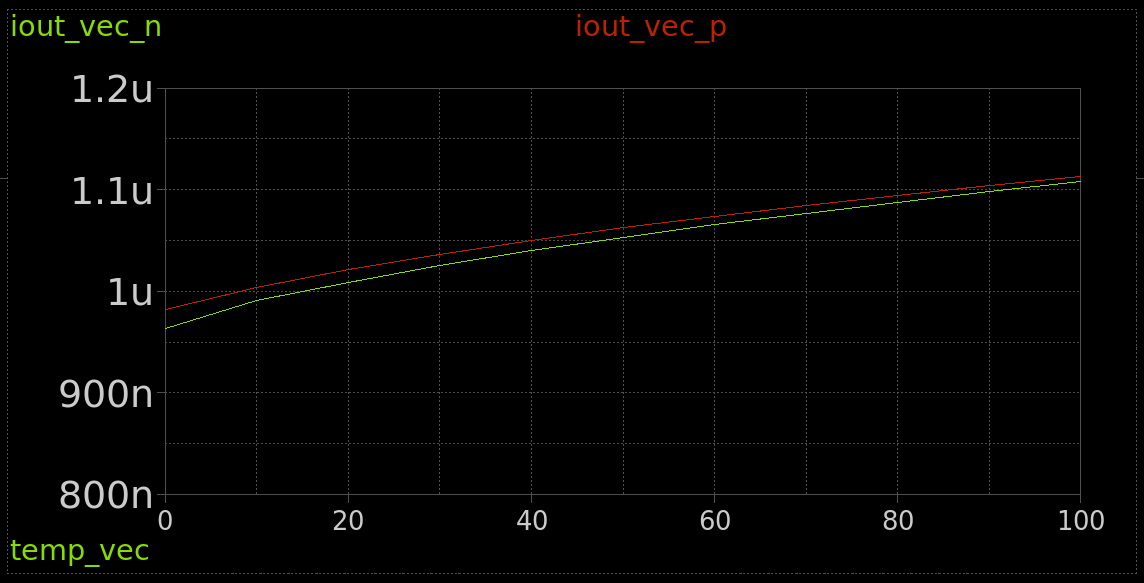

A temperature sweep was performed using the schematic-only netlist to characterize the temperature dependence of the output currents:

Here, iout_vec_n is the NMOS output (sink) current, and iout_vec_p is the

PMOS output (source) current. The total variation in both currents is slightly

more than 10% from 0 to 100 degrees C. While this would be significant for a

precision circuit, it is less than half the variation of the PLL bias generator,

which is more than sufficient for this application.

Comparator

A transient, schematic-only simulation was performed on the ADC comparator to characterize hysteresis:

The en and enb pins are deasserted to begin the simulation, then asserted at

10 ns to allow the bias generator to start up. The hysteresis was measured to be

roughly 1.14 V at the TT process corner. A large hysteresis is desirable here

because it allows a larger swing at the output of the integrator, which in turn

means a smaller integrator capacitance is required to guarantee a given minimum

pulse width.

Control interface

This section gives details of the digital control interface for the top-level tile.

Pinout and CSR address map

The control interface for tiny_pll is implemented using an array of 4-bit

control/status registers (CSRs). Pin assignments for the tile are as follows:

| Pin group | Use | Description |

|---|---|---|

ui_in[3:0] |

csr_data_in |

CSR data input. |

ui_in[7:4] |

csr_addr_in |

CSR address input. |

uio_in[0] |

clk_csr |

CSR clock input, rising-edge sensitive. |

clk |

clk_in |

PLL reference clock input. |

uo_out[3:0] |

clk_out |

PLL clock outputs. |

uo_out[4] |

adc_out |

ADC output for control voltage measurement. |

All other I/O pins are unused. Data is clocked into the CSRs at the rising edge

of clk_csr. There are 13 CSRs:

| Address | Register name | Description |

|---|---|---|

0x0 |

div_fb_0 |

PLL channel 0 feedback divider ratio. |

0x1 |

div_out_0 |

PLL channel 0 output divider ratio. |

0x2 |

div_fb_1 |

PLL channel 1 feedback divider ratio. |

0x3 |

div_out_1 |

PLL channel 1 output divider ratio. |

0x4 |

div_fb_2 |

PLL channel 2 feedback divider ratio. |

0x5 |

div_out_2 |

PLL channel 2 output divider ratio. |

0x6 |

div_fb_3 |

PLL channel 3 feedback divider ratio. |

0x7 |

div_out_3 |

PLL channel 3 output divider ratio. |

0x8 |

enb |

Active-low enable for PLL channels. |

0x9 |

csr_clk_0_sel |

Input mux selection for PLL channel 0. |

0xA |

csr_clk_1_sel |

Input mux selection for PLL channel 1. |

0xB |

csr_clk_2_sel |

Input mux selection for PLL channel 2. |

0xC |

csr_clk_3_sel |

Input mux selection for PLL channel 3. |

CSR addresses above 0xC are not used. The csr_clk_*_sel registers are used

to select the reference clock source for each of the PLL channels. This feature

allows multiple PLL channels to be connected in series, which enables a wider

range of possible output frequencies. Each PLL can be driven either by

the external reference clock input, or by the output of any of the other 3 PLL

channels. In particular, for csr_clk_0_sel:

csr_clk_0_sel |

PLL channel 0 clock source |

|---|---|

0x0 |

External reference input. |

0x1 |

PLL channel 1 clock output. |

0x2 |

PLL channel 2 clock output. |

0x3 |

PLL channel 3 clock output. |

For csr_clk_1_sel:

csr_clk_1_sel |

PLL channel 1 clock source |

|---|---|

0x0 |

External reference input. |

0x1 |

PLL channel 0 clock output. |

0x2 |

PLL channel 2 clock output. |

0x3 |

PLL channel 3 clock output. |

For csr_clk_2_sel:

csr_clk_2_sel |

PLL channel 2 clock source |

|---|---|

0x0 |

External reference input. |

0x1 |

PLL channel 0 clock output. |

0x2 |

PLL channel 1 clock output. |

0x3 |

PLL channel 3 clock output. |

For csr_clk_3_sel:

csr_clk_3_sel |

PLL channel 3 clock source |

|---|---|

0x0 |

External reference input. |

0x1 |

PLL channel 0 clock output. |

0x2 |

PLL channel 1 clock output. |

0x3 |

PLL channel 2 clock output. |

Values of csr_clk_*_sel greater than 0x3 do not have defined behavior and

should not be used. Note that this implementation allows the creation of

unstable loops where a PLL indirectly feeds its own input. This condition should

also be avoided.

Allowable output frequencies

This section will detail the range of output frequencies that can be achieved

using various combinations of the 4 PLL tiles. For simplicity, we will normalize

to an input frequency f_ref = 1.

Each PLL instance allows for 225 distinct divider settings: The output frequency

is A/B, and both A and B can vary between 1 and 15 due to the 4-bit dividers.

This, however, results in less than 225 possible frequencies, since there can be

multiple divider settings that result in the same output frequency. For example,

there are 15 ways to make an output frequency of 1: 1/1, 2/2, 3/3, etc. The

closest frequency to 1 that can be achieved using a single PLL is 15/14, or

roughly 1.07. For some high-precision applications, a finer tuning range is

desired.

This limitation can be overcome by chaining multiple PLLs, which multiplies their division ratios. For example, one PLL with a ratio of 14/15 followed by another with a ratio of 14/13 results in an output frequency of 196/195, or roughly 1.005. This principle holds for chains of 3 or 4 PLLs, which result in even finer tuning ranges. Obtaining the exact list of frequencies that can be generated using 1 through 4 PLLs is complicated by 2 factors:

- There can be a large number of ways to generate one given division ratio, particularly for values near 1

- When multiple PLLs are chained, the input frequency to each PLL should be constrained to ensure stable loop dynamics

For ease of design, a Python script has been added here that

generates a list of possible division ratios using 1 through 4 PLL slices. The

output of this script is a csv and is given here. This

script is generated using 2 criteria:

- To break ties, choose the configuration using the fewest number of PLL slices, with the smallest feedback division ratio

- When multiple slices are used, the input frequency of each slice should be between 0.8 and 1.2

The csv has the following columns:

| Column name | Description |

|---|---|

r1 |

Numerator of overall output frequency |

r2 |

Denominator of overall output frequency |

a1 |

Numerator of channel 0 division ratio |

b1 |

Denominator of channel 0 division ratio |

a2 |

Numerator of channel 1 division ratio. 0 if channel not used. |

b2 |

Denominator of channel 1 division ratio. 0 if channel not used. |

a3 |

Numerator of channel 2 division ratio. 0 if channel not used. |

b3 |

Denominator of channel 2 division ratio. 0 if channel not used. |

a4 |

Numerator of channel 3 division ratio. 0 if channel not used. |

b4 |

Denominator of channel 3 division ratio. 0 if channel not used. |

The number of unique output frequencies, the closest frequency to 1 and the

implied minimum tuning step at f_ref = 10 MHz are shown below using 1 through

4 channels:

| Channels used | # of possible frequencies | Closest frequency to 1 | Implied tuning step at 10 MHz |

|---|---|---|---|

| 1 | 143 | 15 / 14 | 714 kHz |

| 2 | 1,821 | 196 / 195 | 51.3 kHz |

| 3 | 10,419 | 676 / 675 | 14.8 kHz |

| 4 | 39,958 | 10,648 / 10,647 | 939 Hz |

It should be noted that the tuning range is not linear: the achievable output

frequencies are densest near f = 1, with the tuning steps becoming larger near

the extremes.

Physical design

This section details the design and synthesis of the Tiny Tapeout tile for this project.

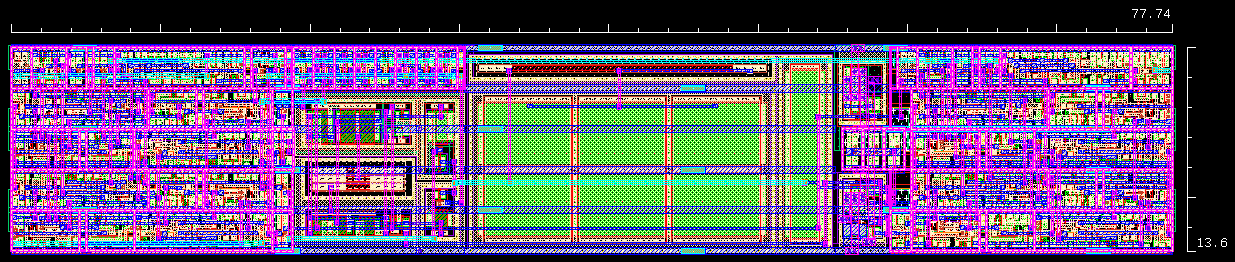

Analog layout

Layout of the custom blocks in this project was performed using klayout. The

top-level layout of tiny_pll is shown below:

The PLL is 77.74 by 13.6 um, for a total area of 1,057 um2. A 1x1 Tiny Tapeout tile has 161 by 111.52 um of usable area, or 17,955 um2. The PLL thus uses only 5.89% of the area of a tile, making it ideal for integration into larger digital or mixed-signal designs without consuming significant area.

The digital sections on the left and right of the macro are the feedback and

output dividers, respectively. The block in the middle of the macro with the

large NMOS devices is the loop filter, to the left of which is the bias

generator, and to the right of which are the VCO and charge pump. The layout is

designed to use a 13.57 um pitch power grid on met4 for compatibility with the

OpenROAD flow. To connect to the global power grid, labels are placed on each

met3 via, and the flow places straps on met4. These straps are connected to

met5 at the top level by Tiny Tapeout.

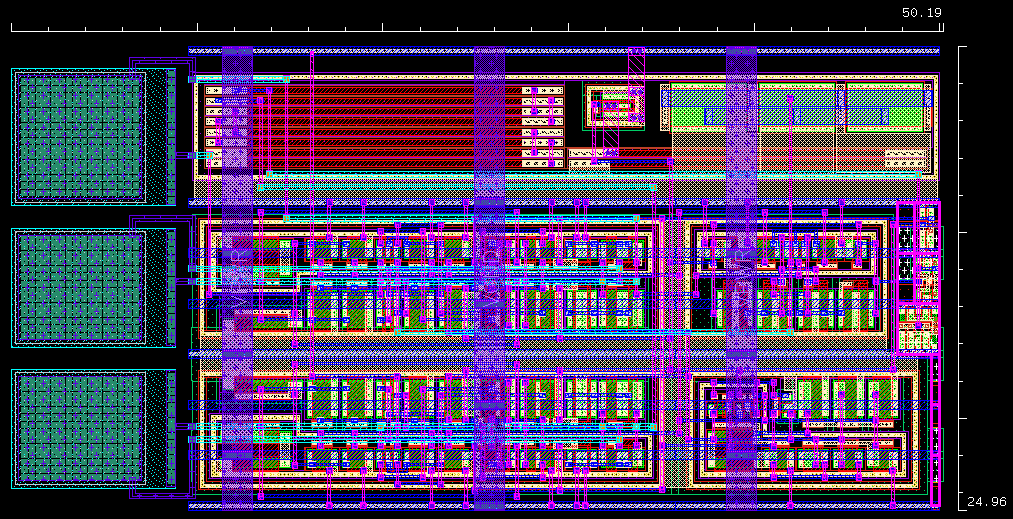

The top-level layout of tiny_adc is shown below:

The ADC is 50.19 um by 24.96 um, or 1,253 um2, which is 6.98% of the area of a

1x1 Tiny Tapeout tile. The capacitors to the left of the macro are compensation

capacitors for the two opamps, and the capacitor used in the integrator. The

opamps, comparator and bias generator are placed near the bottom of the macro,

and the integrator resistors and reference voltage generator are placed above

them. All analog blocks were designed to fit on the sky130_fd_sc_hd standard

cell routing grid with a 2.72 um cell height. The routing grid uses a horizontal

pitch of 0.46 um and a vertical pitch of 0.34 um.

Digital synthesis

While there is greater support in the sky130 community for OpenLANE,

mixed-signal submissions such as this project require a high degree of

customization to ensure proper handling of macro placement, the power delivery

network (PDN) and clock tree synthesis (CTS). Consequently, the OpenROAD Flow

Scripts were used to synthesize this design, with modifications to both the

config.mk and platform files to accommodate the mixed-signal macros.

One particularly difficult customization was the use of a custom sdc

constraint due to the generation of internal clocks in the PLLs. It is desirable

to designate the output nets of the PLLs as clocks, since clocks are by default

routed on higher metal layers, leading to lower wiring resistance. However, it

was observed that OpenROAD does not properly account for gate resizing when

multiple clock trees are used. In particular, despite the addition of a

set_cap_load statement to constraint.sdc in the flow, along with a

create_clock statement with the approprate period, the flow ignored the

external pin load capacitance and placed minimum-sized clkbuf_1 gates at all

clock output pins. This behavior is further complicated by the fact that the

gate resizer is run several times throughout the OpenROAD flow, meaning that

regardless of the initial size of the buffer placed during CTS, the resizer

overrides that selection and places a clkbuf_1 instead.

This issue was resolved by interrupting the flow prior to detailed_route by

calling make cts, followed by make gui_cts. Once in the OpenROAD GUI, the

commands set_cap_load, followed by repair_timing, were used to place buf_4

buffers at each clock output. The flow was then completed by running make,

which fixes any overlaps in the buffer placement and performs detailed routing.

IO

| # | Input | Output | Bidirectional |

|---|---|---|---|

| 0 | csr_data_in[0]: Data input for PLL control registers | clk_out[0]: Channel 0 PLL clock output | clk_csr: Clock input for PLL control registers |

| 1 | csr_data_in[1]: Data input for PLL control registers | clk_out[1]: Channel 1 PLL clock output | |

| 2 | csr_data_in[2]: Data input for PLL control registers | clk_out[2]: Channel 2 PLL clock output | |

| 3 | csr_data_in[3]: Data input for PLL control registers | clk_out[3]: Channel 3 PLL clock output | |

| 4 | csr_addr_in[0]: Address input for PLL control registers | adc_out: Channel 0 control voltage ADC output | |

| 5 | csr_addr_in[1]: Address input for PLL control registers | ||

| 6 | csr_addr_in[2]: Address input for PLL control registers | ||

| 7 | csr_addr_in[3]: Address input for PLL control registers |